2025 Insights: 7 Factors Making Best Spiral Pipe Essential for Industrial Growth

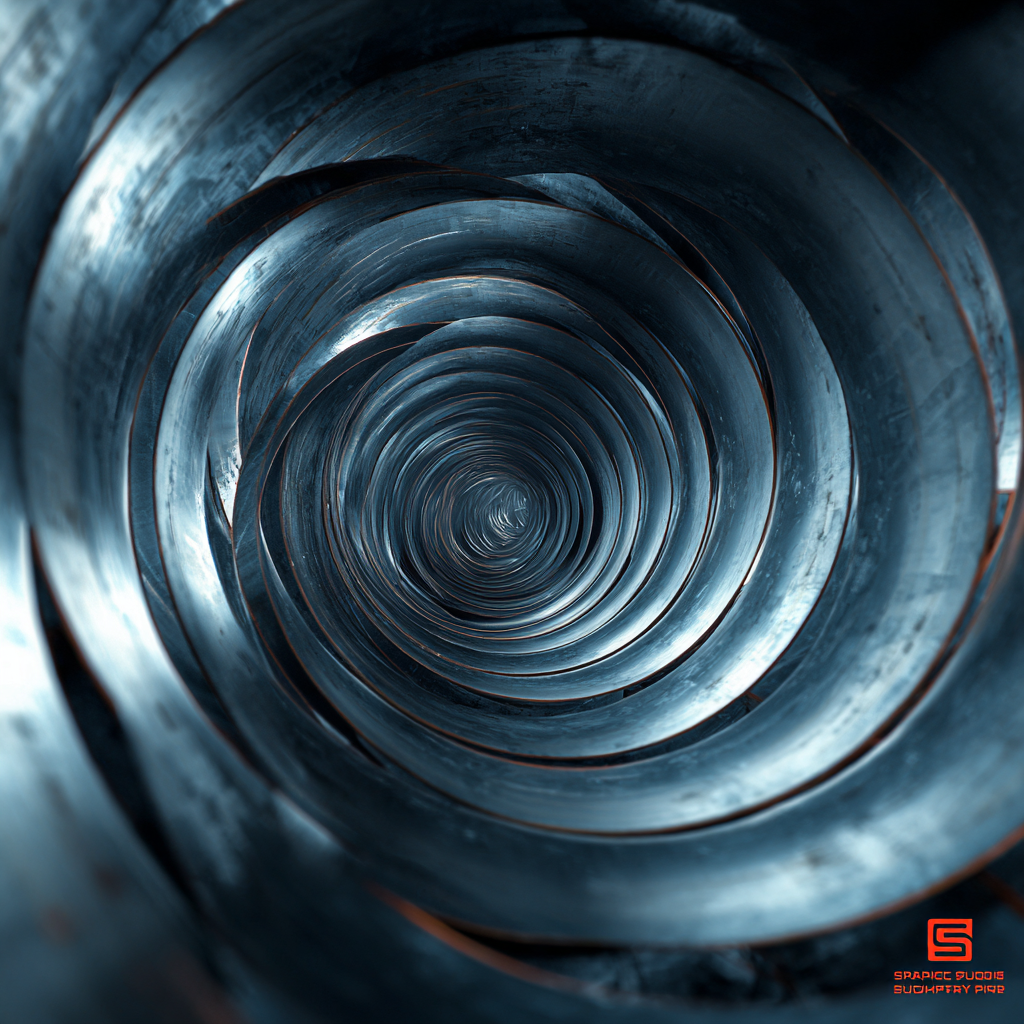

As we venture toward 2025, the industrial landscape is poised for significant transformation, with the demand for advanced manufacturing solutions at an all-time high. Among these solutions, the

Spiral Pipe plays a pivotal role, driven by its unique characteristics that meet the rigorous requirements of modern industrial applications.

According to a report by MarketsandMarkets, the global market for spiral welded pipes is expected to reach

USD 8.3 billion by 2025, growing at a CAGR of 5.2%. This surge is attributed to the increasing need for

durable construction materials within sectors such as oil and gas, water supply, and infrastructure development.

The innovative design of Spiral Pipe not only enhances structural integrity

but also offers cost-effective and efficient installation options, making it an indispensable asset for industrial growth in the coming years.

As we explore the seven critical factors influencing this trend,

it becomes clear that the evolution of Spiral Pipe technology is set to shape the future of various industries.

The innovative design of Spiral Pipe not only enhances structural integrity

but also offers cost-effective and efficient installation options, making it an indispensable asset for industrial growth in the coming years.

As we explore the seven critical factors influencing this trend,

it becomes clear that the evolution of Spiral Pipe technology is set to shape the future of various industries.

The Importance of Spiral Pipe in Modern Manufacturing: A Key to Efficiency

In today's fast-paced manufacturing landscape, efficiency is paramount, and spiral pipes are emerging as a vital component in achieving streamlined operations. Their unique design enables optimal flow characteristics, reducing pressure drops and energy consumption. This innovative piping solution allows industries to maximize throughput while minimizing waste, making it an essential asset for modern manufacturing processes.

Furthermore, spiral pipes are versatile and adaptable, catering to a wide range of industrial applications. From water and wastewater treatment to oil and gas transportation, their robust construction and resistance to corrosion enhance durability and longevity. As manufacturers increasingly prioritize sustainability, the energy-efficient properties of spiral pipes not only contribute to environmental compliance but also lower operational costs, proving that their significance extends beyond mere functionality to encompass economic advantages as well.

Cost-Effectiveness: How Best Spiral Pipe Drives Industrial Profitability

In the pursuit of industrial growth, the cost-effectiveness of materials is paramount. Best spiral pipes, recognized for their superior strength-to-weight ratio and durability, are proving essential in maximizing profitability across various sectors. According to a recent report by Grand View Research, the global market for spiral pipes is expected to reach USD 6.8 billion by 2025, driven not only by their efficiency but also by their reduced installation costs. The ease of installation due to their lightweight nature allows industries to cut down on labor expenses significantly, which is a substantial benefit in tight economic conditions.

Moreover, spiral pipes contribute to lower maintenance costs, enhancing overall operational efficiency. A study from the Engineering Toolbox indicates that the lifespan of spiral pipes can exceed 50 years, minimizing the frequency and costs associated with replacements. Industries utilizing high-quality spiral pipes can experience an up to 20% reduction in total lifecycle costs. This financial advantage underscores the importance of investing in best spiral pipe technology, which positions companies to thrive amidst competitive pressures while ensuring sustainability and reliability in their operations.

Enhancing Durability: Why Quality Spiral Pipes are a Long-term Investment

In the realm of industrial growth, the quality of materials used plays a pivotal role, with spiral pipes emerging as a critical component. When we speak of enhancing durability, it is evident that investing in high-quality spiral pipes offers a multitude of long-term benefits. Unlike their traditional counterparts, these pipes are designed with advanced engineering techniques that allow them to withstand extreme pressures and corrosive environments. This resilience not only reduces the frequency of replacements but also ensures operational efficiency and safety across various applications.

Moreover, the financial implications of using premium spiral pipes cannot be overlooked. While they may come with a higher upfront cost, the longevity and lower maintenance needs translate to significant savings over time. Industries that prioritize durability over short-term expenses position themselves for sustainable growth. By selecting quality spiral pipes, companies not only secure their infrastructure but also enhance productivity, proving that investing in the best materials is fundamentally linked to successful industrial outcomes.

Sustainability in Industry: The Role of Spiral Pipes in Eco-Friendly Practices

Sustainability is becoming increasingly paramount in industrial practices, and spiral pipes play a critical role in driving eco-friendly initiatives. These pipes are known for their efficiency and durability, allowing industries to reduce waste while maximizing resource utilization. According to a report by the International Energy Agency, industrial sectors account for over 30% of global energy consumption. By incorporating high-quality spiral pipes, businesses can significantly enhance their energy efficiency, supporting both operational cost reduction and a lower carbon footprint.

Tip: Consider conducting a life cycle assessment of your current piping systems to identify potential areas for improvement and sustainability gains.

Moreover, spiral pipes have been praised for their recyclability, as they are typically manufactured from steel, a material that can be repurposed endlessly without losing quality. The American Iron and Steel Institute reports that nearly 90% of all steel is recycled in the U.S., underscoring the potential for commercial industries to adopt more sustainable practices. By choosing spiral pipes, companies not only invest in robust infrastructure but also contribute to a circular economy that prioritizes minimal waste and environmental stewardship.

Tip: Partner with suppliers who prioritize sustainable production methods to ensure that your materials align with eco-friendly practices.

Innovation in Design: Cutting-Edge Spiral Pipe Technologies for Future Growth

In the rapidly evolving landscape of industrial construction, the innovation in design of spiral pipes is taking center stage. With their unique ability to handle high pressure and accommodate complex piping systems, spiral pipes are becoming indispensable for various industries, including oil and gas, water treatment, and construction. According to a recent report by MarketsandMarkets, the global spiral pipe market is expected to grow from $5.2 billion in 2022 to $7.9 billion by 2025, driven by these advanced technologies. The incorporation of AI and automation in manufacturing processes enhances precision and reduces waste, ultimately leading to cost-effective solutions.

Tips for Leveraging Spiral Pipe Technology:

Ensure your supply chain partners are equipped with the latest spiral pipe technologies to maintain competitiveness. This will not only improve efficiency but also ensure compliance with regulatory standards that are becoming increasingly stringent.

Additionally, consider investing in training for your workforce to better understand the benefits and applications of these cutting-edge designs. A report from the International Association of Oil & Gas Producers indicates that companies adopting innovative materials can see a reduction in maintenance costs by up to 20%, showcasing the long-term benefits of integrating spiral pipe technologies into industrial operations.