Advantages of Using the Best Wiped Film Evaporator for Efficient Separation

In recent years, the demand for efficient separation processes in industries such as pharmaceuticals and food production has surged, with the wiped film evaporator (WFE) emerging as a pivotal technology. According to a report by MarketsandMarkets, the global evaporator market is projected to reach $4.2 billion by 2025, driven by the growing need for high-efficiency separation methods.

The WFE, renowned for its ability to handle heat-sensitive materials while maintaining product integrity, plays a crucial role in achieving optimal separation and concentration. With the advancement of technology and increasing regulatory pressures, selecting the best Wiped Film Evaporator not only enhances operational efficiency but also aligns with international standards for product quality and safety.

This blog will explore the advantages of using top-tier wiped film evaporators, highlighting their contributions to effective separation and compliance with industry certifications.

The Science Behind Wiped Film Evaporators and Their Efficiency

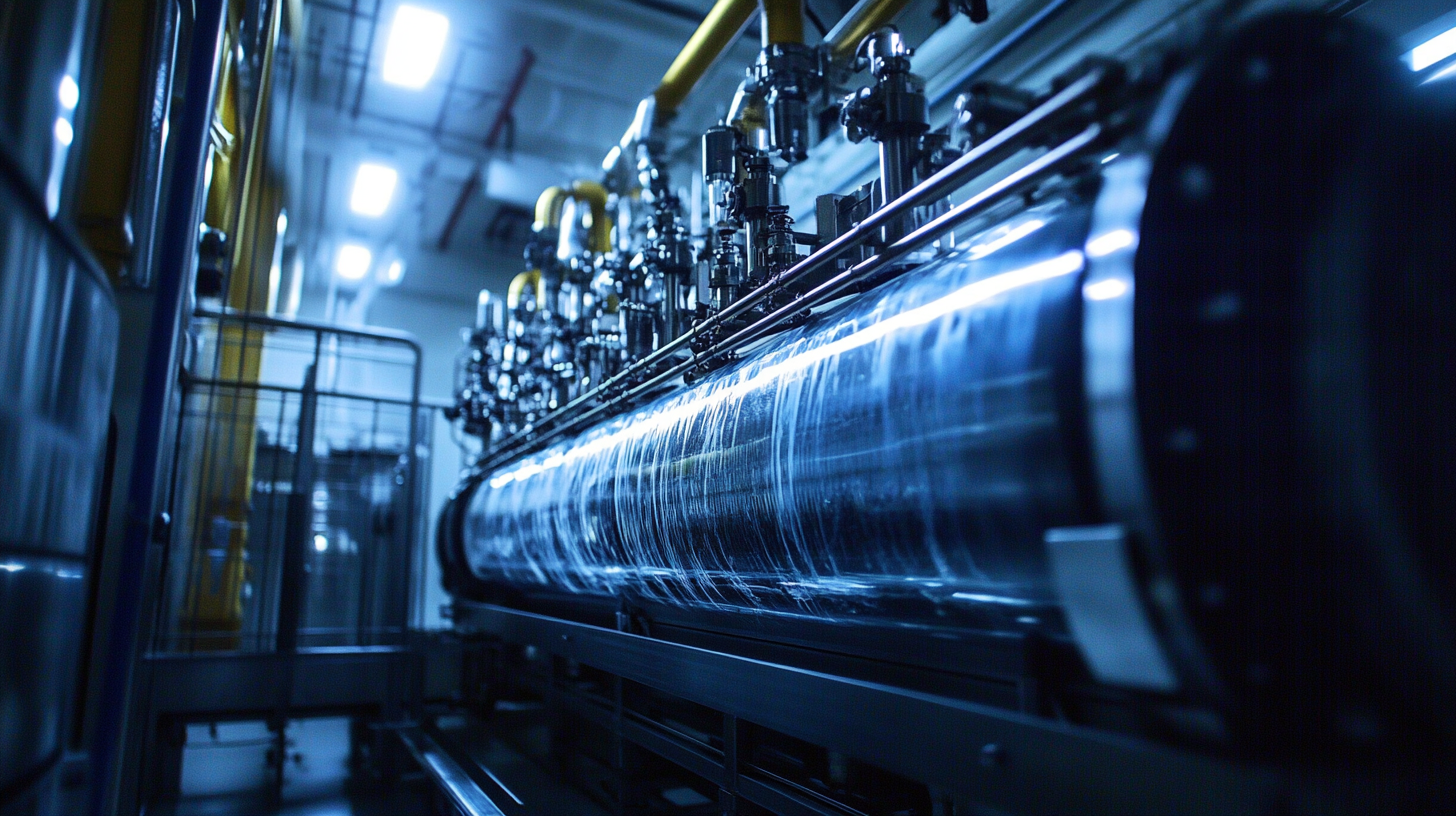

Wiped film evaporators have gained significant attention in various industries due to their unique design and operational efficiency. At the core of their effectiveness is the mechanism by which they facilitate the separation of components in a mixture. The evaporator employs a thin film of liquid that is continuously wiped across heated surfaces. This method not only enhances heat transfer but also minimizes the residence time of the liquid, reducing the chances of thermal degradation of sensitive compounds.

The science behind wiped film evaporators lies in their ability to maintain a consistent film thickness while ensuring maximum surface area exposure to heat. This leads to rapid evaporation and a more efficient process overall. The wiped film design also helps in preventing fouling, which is a common issue in traditional evaporators, ultimately resulting in a more reliable and cost-effective operation. The ability to operate under reduced pressures further contributes to the preservation of volatile substances, making wiped film evaporators a crucial tool in the extraction and purification processes across various applications.

Advantages of Using the Best Wiped Film Evaporator for Efficient Separation

| Feature | Description | Efficiency Impact | Applications |

|---|---|---|---|

| Continuous Operation | Allows for uninterrupted processing of materials | Increases throughput and reduces operational costs | Pharmaceuticals, Food Processing |

| High Thermal Efficiency | Minimizes heat losses during evaporation | Enables faster concentration of products | Chemical Industry, Biofuels |

| Versatile Operation | Can handle a variety of feed materials and viscosities | Accommodates different application needs effectively | Essential Oils, Concentrates |

| Quality Product Output | Produces high purity outputs with minimal contaminants | Improves product quality, meeting stringent standards | Pharmaceutical and Cosmetic Industries |

Key Features of the Best Wiped Film Evaporators for Industrial Use

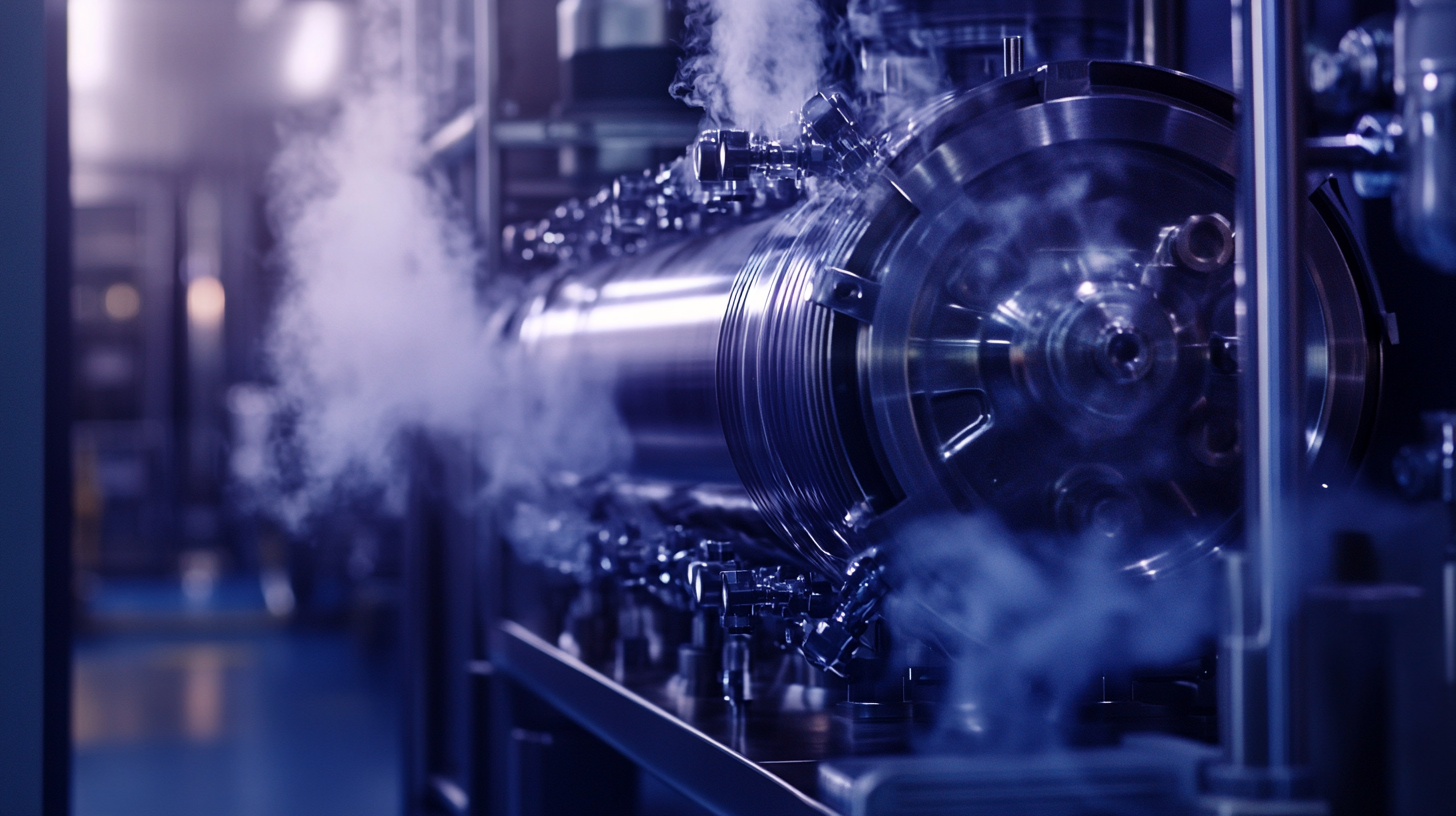

Wiped Film Evaporators (WFE) are becoming increasingly essential in industrial applications due to their efficiency in separating volatile compounds from liquids. The best wiped film evaporators are designed with key features that enhance performance, including a high heat transfer coefficient, low residence time, and the ability to operate at reduced pressures. These features make them particularly suitable for processing heat-sensitive materials, allowing for the recovery of high-quality distillates without compromising product integrity.

According to industry reports, the Wiped Film Evaporators market is projected to grow at a compound annual growth rate (CAGR) of 3% from 2023 to 2029. This growth is driven by a rising demand for efficient separation technologies in sectors such as pharmaceuticals, food and beverage, and biofuels. As companies seek to optimize their production processes, investing in advanced WFE technology becomes a strategic move to enhance operational efficiency and reduce costs. With innovations in design and materials, the best wiped film evaporators are set to play a crucial role in meeting these industry demands.

Benefits of High Purity Separation in Chemical Processing

In the realm of chemical processing, achieving high purity separation is crucial for maximizing product quality and operational efficiency. One of the best methods to achieve this is through the use of advanced wiped film evaporators. According to a report by the American Institute of Chemical Engineers, utilizing high-performance wiped film evaporators can increase separation efficiency by over 30%, significantly reducing the energy consumption compared to traditional methods. This is mainly due to the thin film created on the evaporator surface, which accelerates mass transfer and enhances the evaporation process.

High purity separation not only improves product yield but also minimizes the need for extensive downstream purification steps. The National Center for Biotechnology Information highlights that for biopharmaceutical applications, achieving purity levels of 99% or higher is essential to meet regulatory standards. Wiped film evaporators are particularly effective in separating volatile compounds from complex mixtures, ensuring that end products meet stringent quality specifications while also reducing waste and environmental impact.

By investing in the best wiped film evaporator technology, companies can optimize their chemical processes, leading to higher profitability and compliance with industry standards.

Cost-Effectiveness of Wiped Film Evaporation Technology

Wiped film evaporation technology has gained significant attention due to its cost-effectiveness in various industrial applications. By efficiently separating components, this technology not only saves time but also reduces operational expenses. The ability to handle viscous fluids makes wiped film evaporators particularly advantageous for a range of products, including oils and polymers, maximizing yield while minimizing energy consumption.

One notable aspect of wiped film evaporation is its ability to operate at lower temperatures, which preserves the quality of heat-sensitive products. This characteristic can lead to higher product purity and better end-user experiences. Moreover, the compact design of these units facilitates easy integration into existing manufacturing workflows, making it an attractive option for businesses aiming to enhance their processing capabilities without extensive overhauls.

**Tips for Maximizing Efficiency:**

- Regular maintenance of the evaporator can prevent downtime and costly repairs.

- Ensure the correct setup of feed rates to optimize the separation process.

- Consider investing in advanced automation systems to enhance precision and consistency in operation, thereby further reducing costs.

Cost-Effectiveness of Wiped Film Evaporation Technology

This chart illustrates the advantages of wiped film evaporators in terms of operational efficiency and cost savings in comparison to traditional separation methods.

Applications of Wiped Film Evaporators Across Various Industries

Wiped film evaporators are integral to a wide range of industries, enhancing separation processes and improving product quality. In the food and beverage sector, for example, they are used for the efficient concentration of juices and extraction of essential oils. According to a report by the Food Processing Association, employing wiped film technology can increase yield by up to 15% compared to traditional evaporation methods, making it a favorite among manufacturers seeking to optimize productivity.

In the pharmaceutical industry, wiped film evaporators facilitate the removal of solvents from heat-sensitive compounds, crucial for maintaining drug efficacy. A study by the International Society for Pharmaceutical Engineering (ISPE) highlights that these systems can achieve evaporation rates exceeding 90% with minimal thermal degradation. This efficiency is particularly valued in producing active pharmaceutical ingredients (APIs) where purity and potency are paramount.

Overall, the versatility and effectiveness of wiped film evaporators enable diverse applications across industries, reinforcing their status as a critical technology for separation processes.