The Future of Tublar Heat Exchangers in 2025 An In-depth Comparison of Leading Technologies

As we look toward 2025, the landscape of Tublar Heat Exchangers is set to evolve significantly, driven by advancements in technology and changing industry demands. According to the latest market research, the global heat exchanger market is projected to reach approximately $28 billion by 2026, with tubular designs playing a crucial role due to their efficiency and versatility. These systems are becoming increasingly essential in industries ranging from oil and gas to pharmaceuticals, where efficiency can lead to significant cost savings. In this blog, we will delve into an in-depth comparison of the leading tubular heat exchanger technologies, exploring their unique features, applicability in various scenarios, and best practices for integration. By understanding the distinctive attributes of each technology, stakeholders can make informed decisions that align with their operational goals and sustainability objectives.

Emerging Trends in Tubular Heat Exchanger Technology for 2025

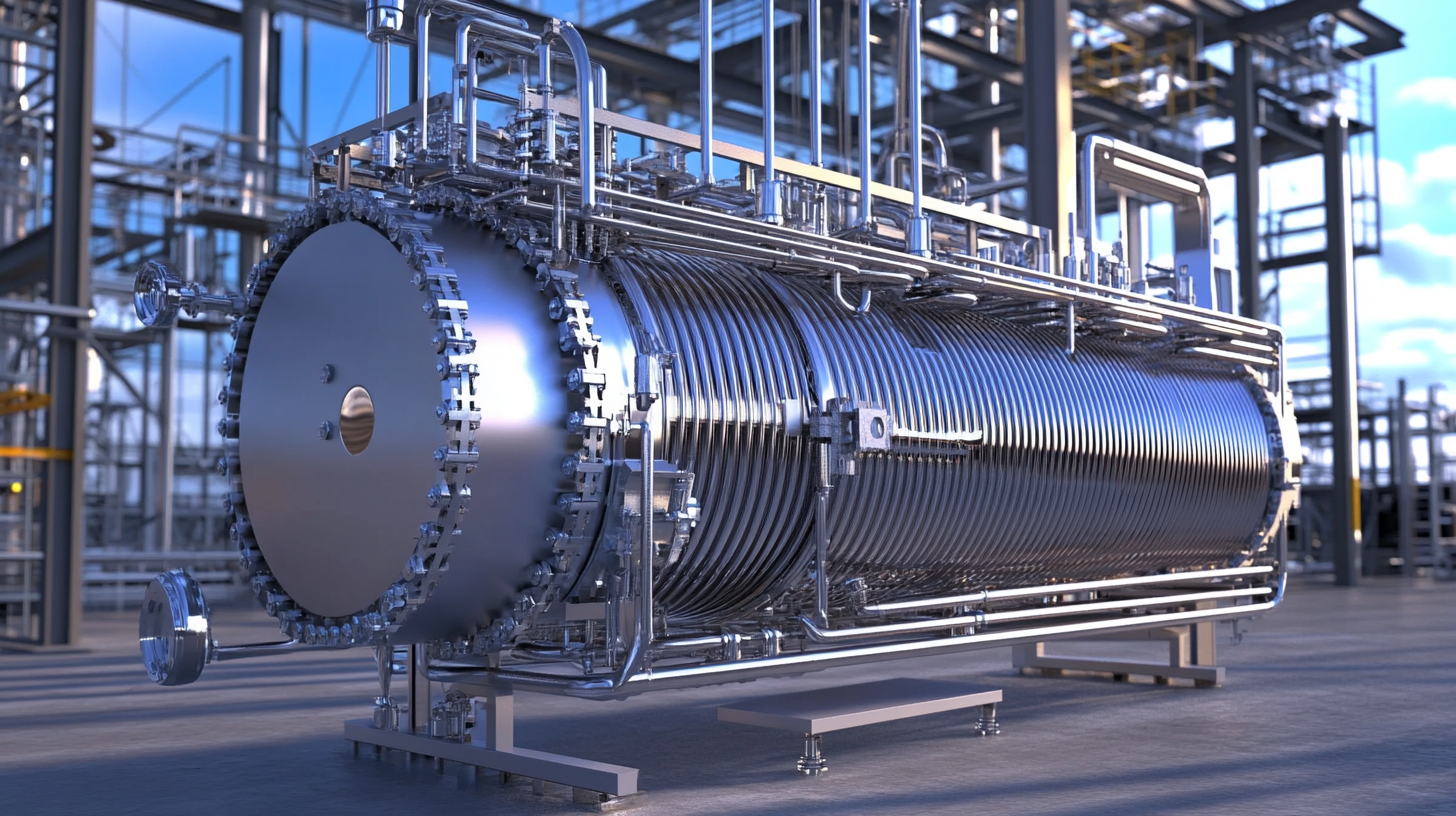

As we look ahead to 2025, the landscape of tubular heat exchanger technology is poised for significant evolution. Emerging trends suggest a shift towards more energy-efficient designs, necessitating innovations that enhance thermal performance while reducing environmental impact. One notable trend is the integration of advanced materials such as high-strength alloys and composites, which improve heat transfer efficiency and durability, making them ideal for demanding applications in industries such as chemicals and power generation.

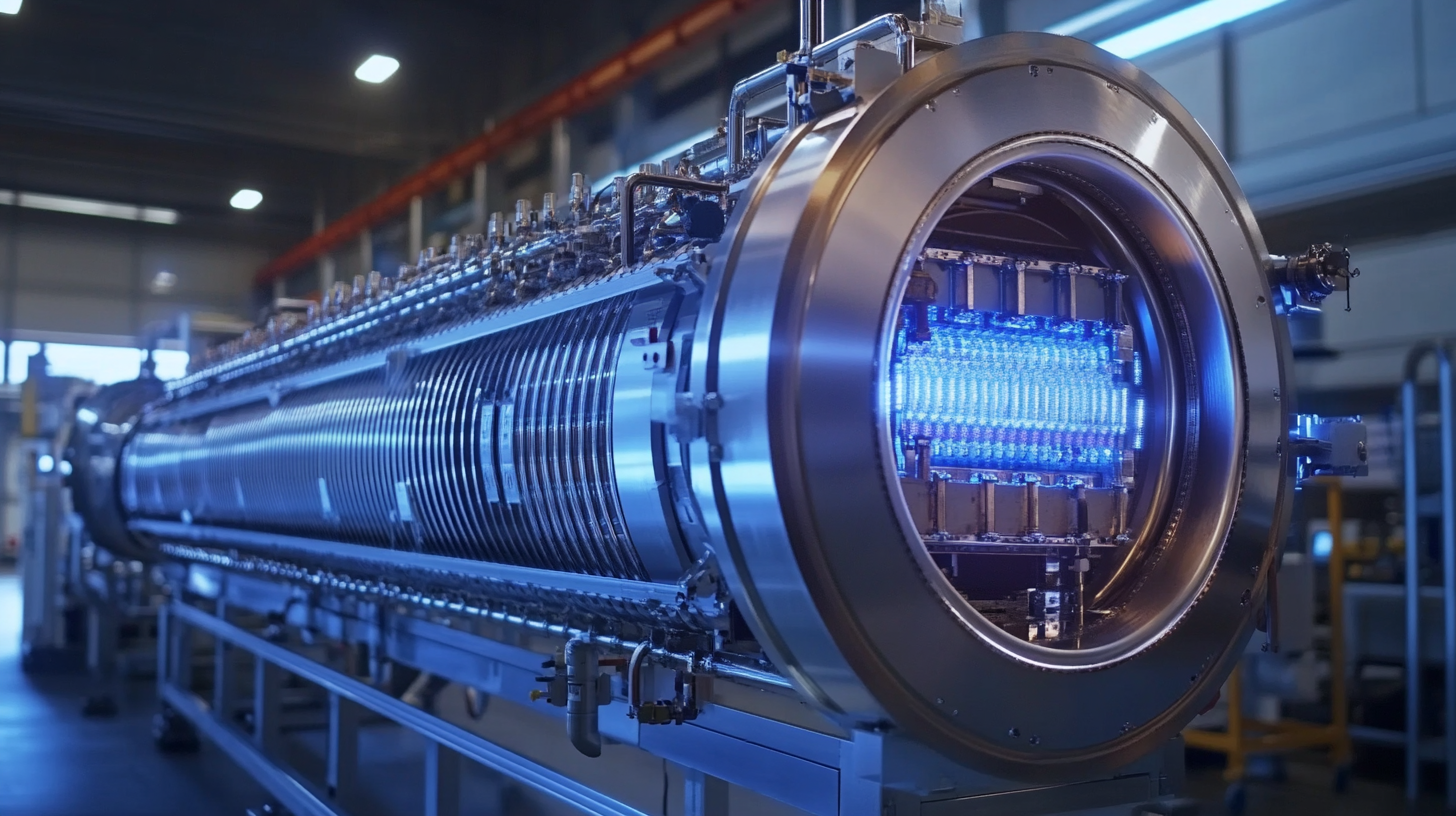

Furthermore, the adoption of intelligent monitoring systems is gaining traction. These systems utilize IoT and AI technologies to optimize heat exchanger performance in real-time, allowing for predictive maintenance and reducing downtime. This trend signifies a move towards more automated and smarter plant operations, where data-driven insights lead to increased efficiency and cost savings. Additionally, modular designs are becoming increasingly popular, allowing for easier installation and maintenance while providing flexibility in scaling operations. This shift is redefining how tubular heat exchangers are engineered, aligning with the industry's focus on sustainability and operational excellence.

The Future of Tubular Heat Exchangers in 2025

This chart illustrates the comparative performance of various tubular heat exchanger technologies projected for the year 2025. The data highlights emerging trends and the anticipated efficiency improvements across different parameters.

Comparative Analysis of Energy Efficiency Across Leading Technologies

As we approach 2025, the landscape of tubular heat exchangers is evolving rapidly, driven by advancements in technology and a growing emphasis on energy efficiency. A comparative analysis reveals that several leading technologies are vying for dominance, each with unique benefits that cater to diverse industrial applications.

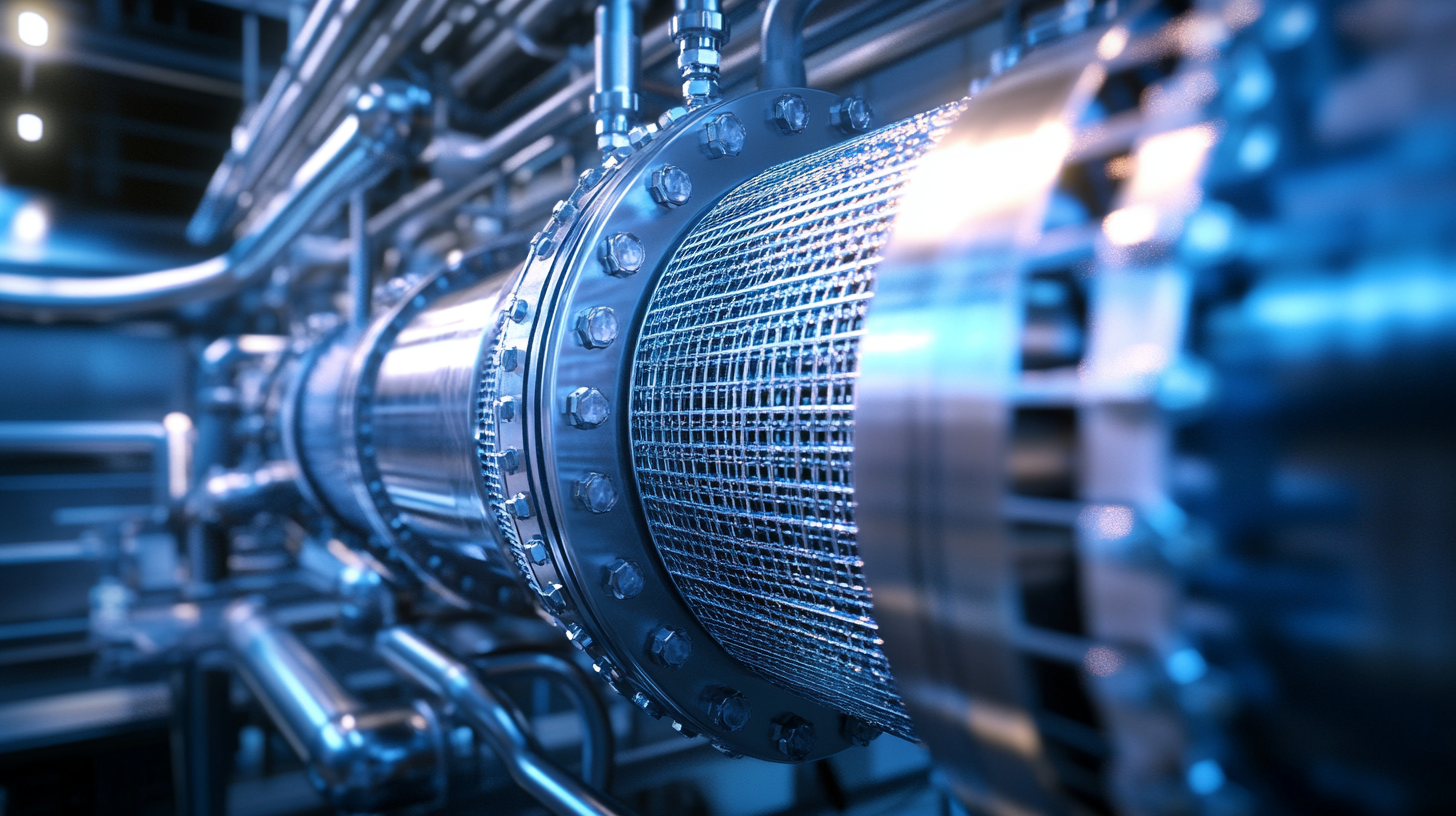

First, traditional shell-and-tube designs remain popular due to their robust performance in high-pressure environments, but emerging technologies, such as compact heat exchangers, are gaining traction for their lower footprint and improved heat transfer rates. Innovations in materials, like the use of corrosion-resistant alloys, further enhance energy efficiency by minimizing losses associated with wear and tear.

Additionally, modern approaches like augmented and microchannel designs offer significant improvements in thermal performance by increasing surface area and optimizing flow dynamics. These advancements not only reduce energy consumption but also support stringent environmental regulations. As industries seek sustainable solutions, the competition among these technologies will likely intensify, fostering a new era of efficiency in tubular heat exchanger applications.

Advancements in Materials: Enhancing Tubular Heat Exchanger Performance

The advancements in materials used in tubular heat exchangers are paving the way for enhanced performance and efficiency in the coming years. As we approach 2025, innovations in alloys and composites are set to revolutionize the design and functionality of these essential components. By utilizing materials that offer superior thermal conductivity and corrosion resistance, manufacturers can create tubular heat exchangers that not only perform better but also have a longer lifespan.

Tip: When selecting a tubular heat exchanger, consider the material properties that best suit your operational environment. For example, enhanced nickel alloys can withstand higher temperatures and aggressive chemicals, making them ideal for industries like petrochemicals and power generation.

Moreover, the integration of advanced manufacturing techniques, such as 3D printing and additive manufacturing, allows for more intricate designs that optimize fluid flow and heat transfer. These approaches facilitate the development of lighter and more compact heat exchangers without compromising performance.

Tip: Stay updated on the latest research and technical developments in heat exchanger materials. This knowledge can help you make informed decisions when upgrading or purchasing new systems for your processes, ensuring maximum efficiency and reliability.

The Future of Tubular Heat Exchangers in 2025: An In-depth Comparison of Leading Technologies

| Technology | Material | Thermal Conductivity (W/m·K) | Weight (kg/m2) | Efficiency (%) | Cost ($/m2) |

|---|---|---|---|---|---|

| Plate-type Tubular | Stainless Steel | 16.2 | 70 | 92 | 200 |

| Spiral Tubular | Copper | 401 | 60 | 95 | 350 |

| Double-Pipe | Aluminum | 205 | 75 | 90 | 150 |

| Shell-and-Tube | Titanium | 21.9 | 85 | 88 | 450 |

Cost-Effectiveness and ROI: Evaluating Top Technologies for 2025

As we approach 2025, the rapid evolution of tubular heat exchangers becomes increasingly significant, not only due to technological advancements but also because of the pressing need for cost-effectiveness and high return on investment (ROI). A recent analysis projected that companies investing in leading heat exchanger technologies could see cost savings of up to 20% in operational expenses, which is crucial in an era where margin pressures are intense. Additionally, the combination of innovative designs and materials can enhance thermal efficiency by 30%, driving further financial benefits.

The integration of AI and automation is expected to revolutionize the maintenance and operation of tubular heat exchangers. With AI’s capacity to streamline workflows and improve data quality, manufacturers can optimize performance while minimizing downtime. Reports indicate that industries adopting AI-driven technologies can achieve ROI improvements of up to 40% compared to those relying on traditional methods. This trend will not only increase competitiveness but also foster sustainability in energy consumption, positioning tubular heat exchangers as a key player in the future industrial landscape.

Sustainability Considerations: Eco-Friendly Innovations in Heat Exchangers

In the rapidly evolving landscape of heat exchangers, sustainability has emerged as a pivotal consideration for technological advancement. The global push for eco-friendly innovations, as emphasized in a recent report by MarketsandMarkets, projects that the heat exchanger market will reach $28 billion by 2025, with a significant shift towards environmentally sustainable designs. Leading manufacturers are now prioritizing materials that not only enhance efficiency but also reduce carbon footprints. For instance, the adoption of innovative heat transfer fluids and recyclable materials contributes to lowering energy consumption and waste, aligning with international sustainability goals.

Furthermore, the integration of advanced heat exchanger systems, such as those utilizing graphene or advanced composite materials, demonstrates tremendous potential for energy efficiency. According to a study published by the International Energy Agency (IEA), optimizing heat exchanger performance could result in energy savings of up to 25% in certain industrial applications. As industries continue to face pressure to reduce greenhouse gas emissions, these developments indicate that the future of tubular heat exchangers will heavily lean on sustainable solutions that not only meet performance standards but also address the critical need for ecological responsibility.