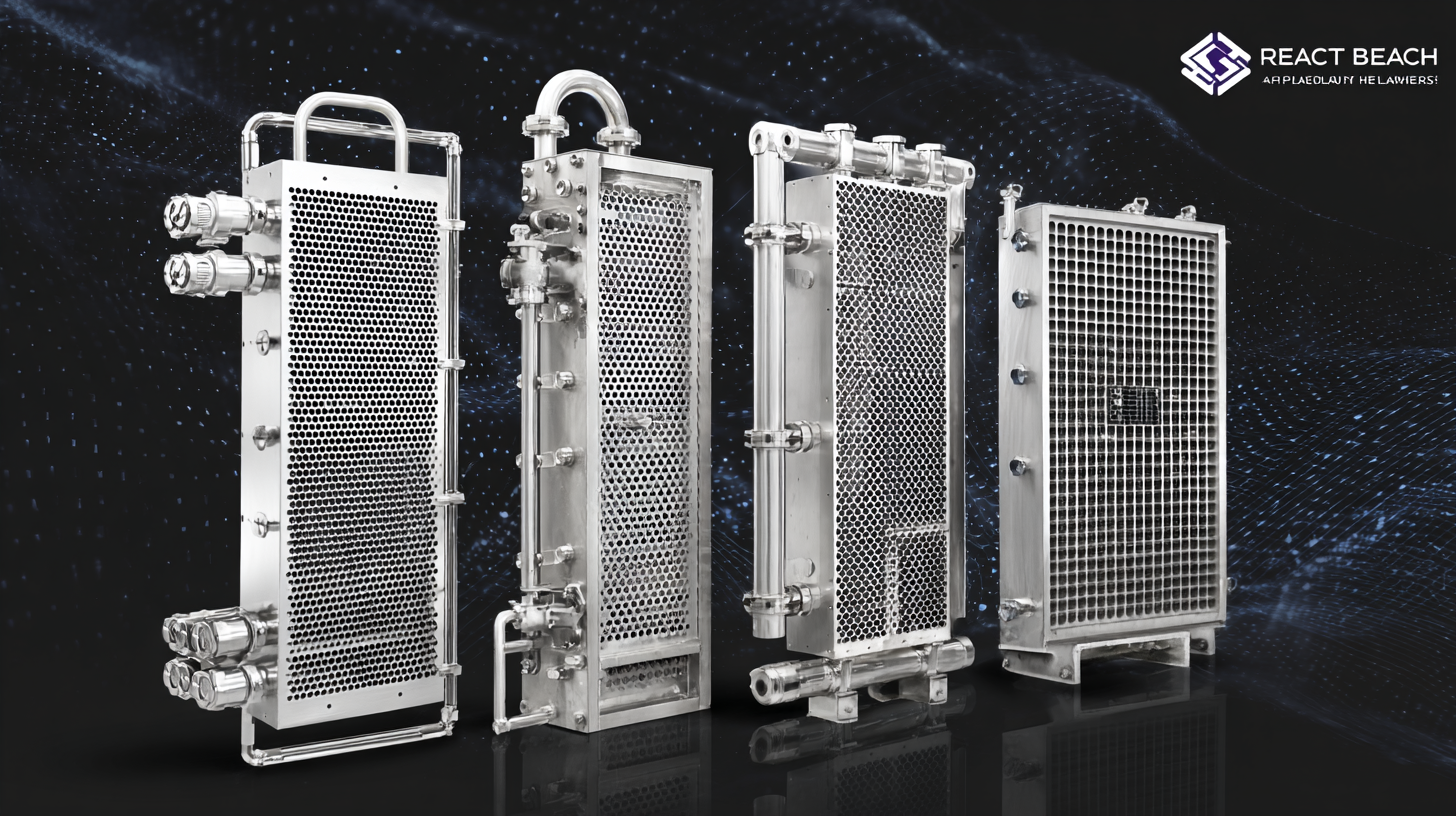

Global Reach of Best Plate Type Heat Exchangers Quality Manufacturing Leads the Market

The global market for Plate Type Heat Exchangers is experiencing significant growth, driven by rising energy efficiency demands and advancements in manufacturing techniques. According to a recent report by MarketsandMarkets, the heat exchanger market is projected to reach USD 21.9 billion by 2025, expanding at a CAGR of 8.4% from 2020. This surge is indicative of an increasing reliance on innovative thermal management solutions across various industries, including chemical processing, HVAC, and food and beverage.

The efficiency, compact design, and adaptability of Plate Type Heat Exchangers make them a preferred choice for many applications. As quality manufacturing practices evolve, the ability to produce these devices at scale while maintaining high standards will be crucial for market leaders seeking to capitalize on this growing demand. In this blog, we will explore how quality manufacturing of Plate Type Heat Exchangers contributes to their global reach and market leadership.

Advantages of After-Sales Service in Plate Type Heat Exchanger Market

In the competitive landscape of plate type heat exchangers, after-sales service plays a crucial role in not only retaining customers but also enhancing the overall market experience. When manufacturers prioritize robust after-sales support, they foster long-term relationships with clients, ensuring that any operational challenges are promptly addressed. This commitment to service not only builds trust but also encourages repeat business, which is essential for market stability, particularly in global markets.

Furthermore, a strong after-sales service network allows manufacturers to gather valuable feedback from users, enabling continuous product improvement. With detailed insights into the performance of heat exchangers in various applications, manufacturers can refine their designs, making them more efficient and reliable.

As customers experience the benefits of high-quality customer support, including timely maintenance and troubleshooting, they are more likely to promote the brand, contributing to organic growth and enhancing the company's reputation in the marketplace. This symbiotic relationship between product performance and customer service ultimately drives the success of plate type heat exchangers in the industry.

Impact of Quality Manufacturing on Maintenance Costs for Heat Exchangers

The impact of quality manufacturing on maintenance costs for heat exchangers is significant and cannot be overlooked. According to a recent report by Grand View Research, the global market for heat exchangers is expected to reach $28.56 billion by 2025, driven largely by growing demand for energy-efficient systems across various industries. Quality manufacturing plays a crucial role in extending the lifespan of heat exchangers, thereby reducing the frequency and costs associated with maintenance and repairs. High-quality materials and precise engineering ensure that these heat exchangers perform efficiently under high-pressure conditions, which is essential for minimizing unexpected downtime.

Tip: Regularly assess and choose heat exchangers from reputable manufacturers renowned for quality assurance. This initial investment can lead to long-term savings by drastically reducing maintenance costs.

Maintenance costs can be further diminished by implementing predictive maintenance strategies, which leverage IoT technology and machine learning to anticipate equipment failures. According to a study by McKinsey, companies that employ predictive maintenance can reduce maintenance costs by 10-40% compared to traditional methods. By selecting heat exchangers that are built to stringent quality standards, businesses can enjoy longer service intervals and minimize the likelihood of costly repairs.

Tip: Integrate advanced monitoring systems with your heat exchangers to optimize operational efficiency and proactively address potential issues before they escalate.

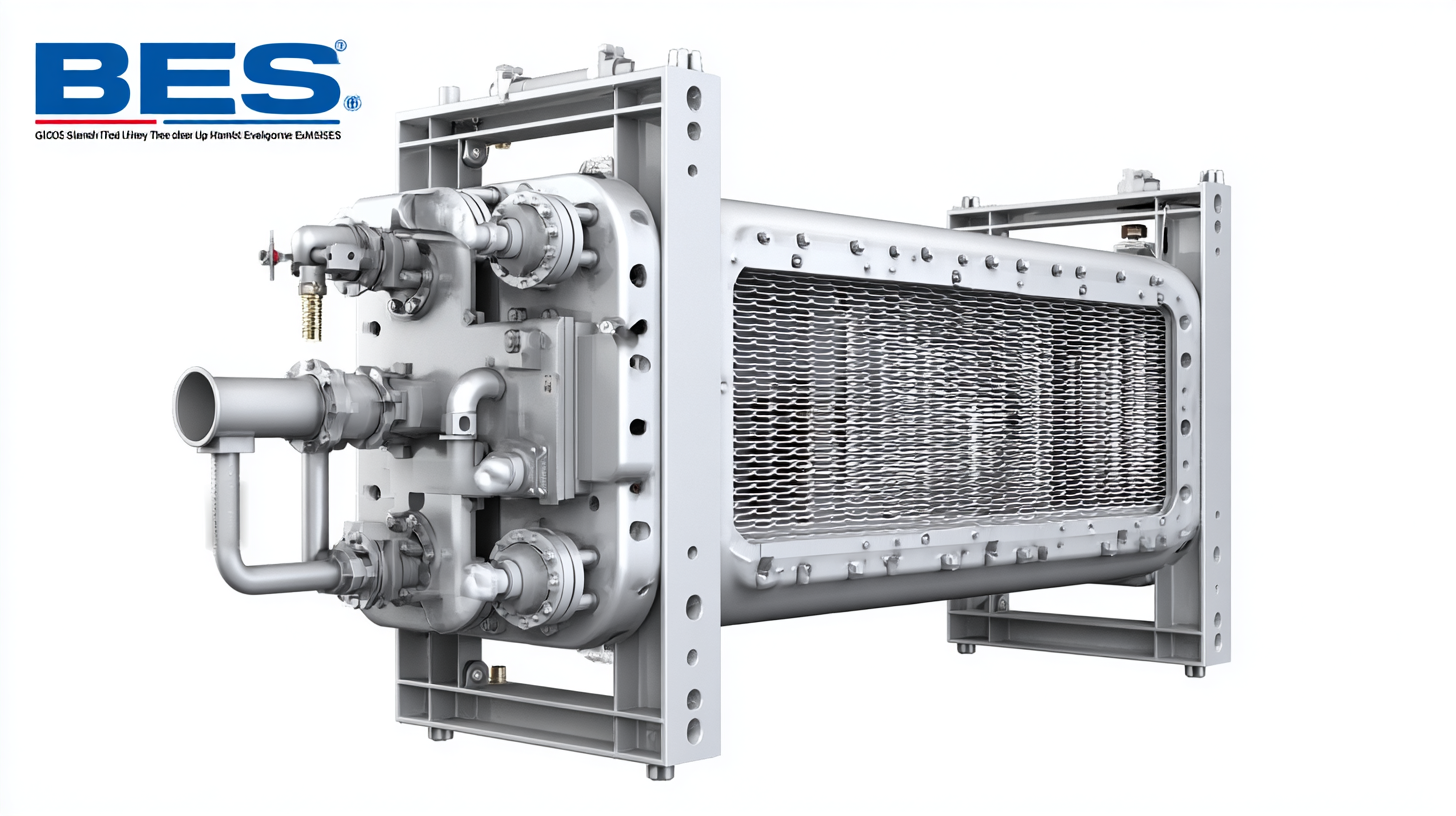

Key Factors in Choosing the Right Heat Exchanger for Optimal Performance

When selecting a heat exchanger, understanding the key factors that influence performance is crucial. One of the primary considerations is the type of fluid being processed. Different fluids have varying thermal characteristics; for instance, viscous liquids may require specific designs to ensure maximum heat transfer efficiency. Moreover, the operating temperatures and pressures play a significant role in determining the right heat exchanger. Choosing a unit that can handle your specific operational demands without compromising safety or efficiency is essential.

When selecting a heat exchanger, understanding the key factors that influence performance is crucial. One of the primary considerations is the type of fluid being processed. Different fluids have varying thermal characteristics; for instance, viscous liquids may require specific designs to ensure maximum heat transfer efficiency. Moreover, the operating temperatures and pressures play a significant role in determining the right heat exchanger. Choosing a unit that can handle your specific operational demands without compromising safety or efficiency is essential.

Tip: Always consider the maintenance requirements of the heat exchanger. Some designs may allow for easier cleaning and servicing, reducing downtime and operational costs over time.

Another critical factor to consider is the material of construction. Corrosion resistance, thermal conductivity, and durability are vital to ensuring long-term reliability and efficiency. It's essential to match the materials with the fluid types and environmental conditions to minimize wear and prolong service life.

Tip: Conduct a thorough cost-benefit analysis when choosing materials; sometimes, investing in higher-quality materials can lead to significant savings in maintenance and replacement costs down the line.

Strategies to Improve After-Sales Support for Heat Exchangers

In the competitive landscape of heat exchanger manufacturing, after-sales support has emerged as a critical factor that can greatly enhance customer satisfaction and loyalty. According to a recent report by MarketsandMarkets, the global heat exchanger market is projected to reach $22.5 billion by 2025, underscoring the importance of not only high-quality products but also robust after-sales services. As companies strive to capture a larger share of this expanding market, investing in comprehensive after-sales support has become essential.

To improve after-sales support, manufacturers can adopt several key strategies. First, implementing a proactive maintenance program can help identify potential issues before they escalate, significantly reducing downtime and repair costs. A study from ResearchAndMarkets indicates that predictive maintenance can lower maintenance costs by as much as 20-25%. Additionally, offering training programs for clients on the proper handling and maintenance of heat exchangers can empower them to maximize the longevity and efficiency of their systems. By prioritizing these strategies, manufacturers not only enhance their service offerings but also build stronger relationships with their customers, ensuring sustained growth in an increasingly demanding market.

Global Reach of Best Plate Type Heat Exchangers Quality Manufacturing Leads the Market - Strategies to Improve After-Sales Support for Heat Exchangers

| Region | Market Share (%) | Annual Growth Rate (%) | Customer Satisfaction Rating (out of 10) | After-Sales Support Rating (out of 10) |

|---|---|---|---|---|

| North America | 25 | 4.5 | 8 | 7.5 |

| Europe | 30 | 3.8 | 9 | 8.2 |

| Asia Pacific | 35 | 5.0 | 7.5 | 7.0 |

| Latin America | 5 | 2.5 | 6.5 | 6.0 |

| Middle East & Africa | 5 | 3.2 | 7.0 | 6.8 |

Understanding the Role of Maintenance in Extending Heat Exchanger Lifespan

Preventative maintenance plays a critical role in extending the lifespan of heat exchangers, particularly in manufacturing facilities where efficiency is paramount. According to industry reports, proactive maintenance can reduce downtime by up to 20%, significantly enhancing operational efficiency while minimizing waste. Implementing a robust heat transfer fluid maintenance program not only leads to smoother operations but also safeguards the longevity of heat exchangers, which are pivotal to the overall functionality of numerous engineering systems.

Innovation in maintenance strategies, such as the adoption of AI-driven predictive maintenance, is transforming how equipment is managed in sectors like oil and gas. A recent study highlights that predictive maintenance can identify potential equipment failures before they occur, reducing maintenance costs by 10-30% while increasing the reliability and performance of critical components. Furthermore, advancements in repair techniques for technologies like shell-and-tube heat exchangers are showing promise in prolonging their operational life. Such approaches are essential as industries strive for sustainable practices while maintaining high performance in their heat exchange systems.