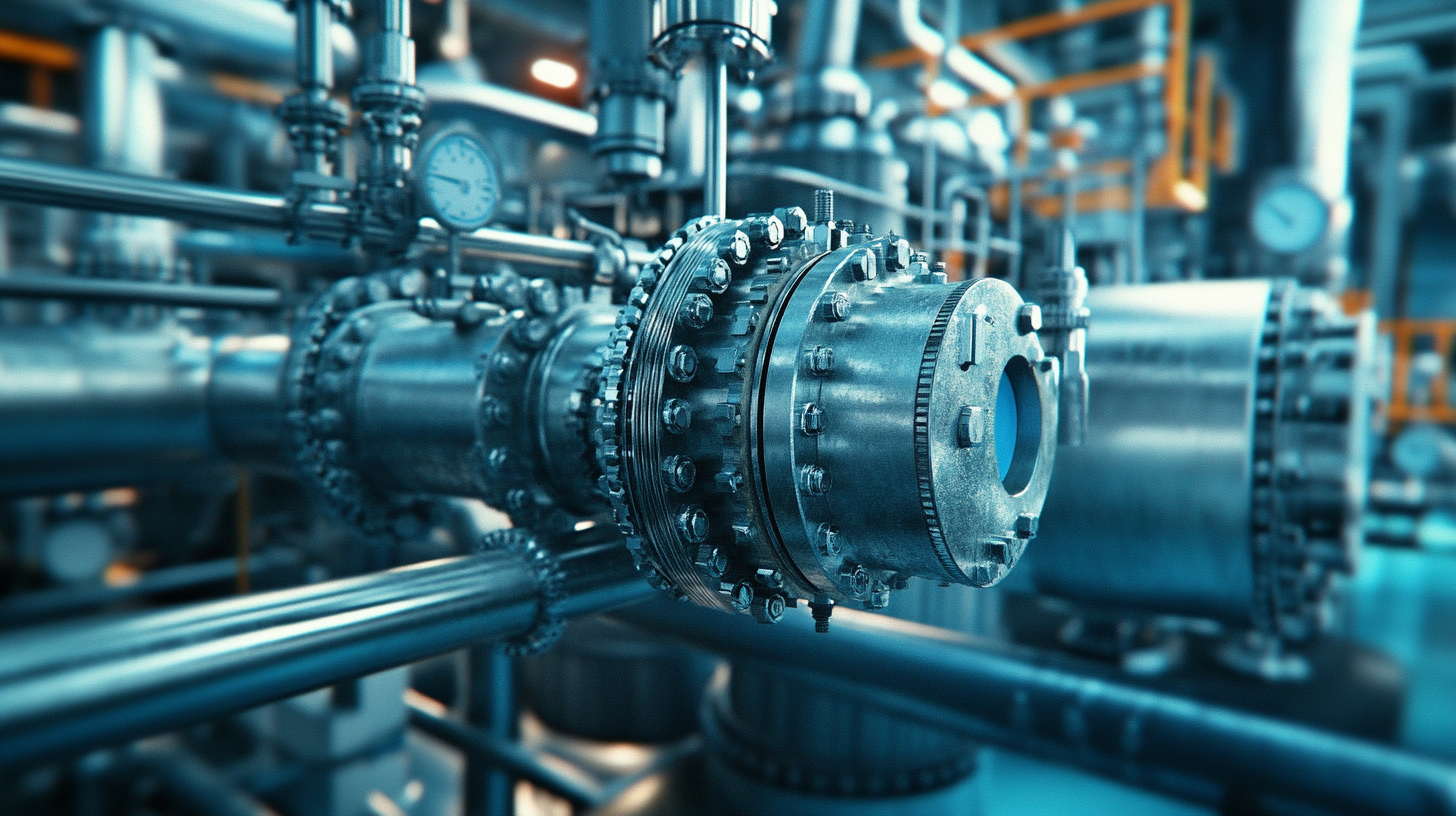

Ultimate Guide to Selecting the Best Tube Exchanger for Your Industrial Needs

In today's competitive industrial landscape, selecting the right tube exchanger is crucial for optimizing thermal efficiency and ensuring compliance with industry standards. According to a report by the International Energy Agency, industrial heat exchangers can account for up to 30% of the total energy consumption in manufacturing processes. This highlights the importance of choosing a tube exchanger that not only meets operational needs but also adheres to stringent import and export certifications prevalent in various regions. Furthermore, a recent market analysis indicates a projected growth rate of 4.5% in the tube exchanger segment over the next five years, driven by advancements in technology and increasing demand for energy-efficient solutions. In this guide, we will delve into essential criteria for selecting the best tube exchanger tailored to your specific industrial requirements, ensuring both performance and compliance in a rapidly evolving market.

Key Factors to Assess When Choosing Tube Exchangers for Industrial Applications

When selecting the best tube exchanger for your industrial applications, several key factors must be assessed to ensure optimal performance and efficiency. First, consider the heat transfer efficiency, which significantly impacts energy consumption. According to a recent industry report, a well-designed tube exchanger can enhance heat transfer by up to 30% compared to standard designs. In addition, the material of the tubes plays a crucial role, as it affects corrosion resistance and thermal conductivity. Many industries opt for stainless steel or exotic alloys to withstand harsh environments, which can increase the upfront cost but lead to longer service life and lower maintenance expenses.

Tip: Always evaluate the specific fluids involved in your processes, as compatibility with materials can prevent costly failures.

Another vital factor is the pressure drop across the exchanger, which can directly influence operational costs. A high-pressure drop indicates increased pumping costs, which can negate the benefits of improved heat transfer efficiency. It's essential to choose a design that minimizes pressure drop while meeting heat transfer requirements. According to data from the American Society of Mechanical Engineers (ASME), optimizing the tube layout can reduce pressure loss by up to 20%.

Tip: Use computational fluid dynamics (CFD) simulations during the design phase to assess flow patterns and optimize the configuration of your tube exchangers effectively.

Top Material Options for Enhanced Durability in Tube Exchangers

When selecting a tube exchanger for industrial applications, the choice of materials is critical in ensuring enhanced durability and efficiency. Commonly used materials for tube exchangers include stainless steel, titanium, and copper alloys. Stainless steel is favored for its excellent resistance to corrosion and high temperatures, making it suitable for a wide range of applications. Its durability allows tube exchangers to withstand harsh operating conditions, ultimately reducing maintenance costs and extending the lifespan of the equipment.

On the other hand, titanium stands out for applications involving aggressive fluids or environments. It offers superior resistance to both corrosion and erosion, making it ideal for chemical processing industries. Although it comes at a higher initial cost, the long-term benefits of reduced failure rates and increased operational efficiency often outweigh the investment. Lastly, copper alloys are commonly used for their superior thermal conductivity, which enhances heat transfer efficiency. However, they are best suited for non-corrosive applications. By carefully selecting the appropriate material based on the specific operational conditions and fluid properties, industrial users can significantly enhance the reliability and performance of their tube exchangers.

Material Options for Tube Exchangers

Understanding Heat Transfer Efficiency: A Key Metric in Tube Exchanger Selection

When selecting a tube exchanger for your industrial needs, understanding heat transfer efficiency is crucial. This metric determines how effectively a heat exchanger can transfer thermal energy between two fluids. High heat transfer efficiency not only ensures optimal operation but also enhances the overall productivity of industrial processes. It is essential to evaluate the design and material of the tube exchanger, as these factors significantly influence its performance in heat exchange applications.

Various parameters affect heat transfer efficiency, including the flow arrangement, surface area, and the type of fluids involved. For instance, counterflow configurations typically offer better efficiency compared to parallel flow systems due to the improved temperature gradient. Additionally, selecting materials with high thermal conductivity can further enhance performance, making it imperative to align your choice with the specific requirements of your operation. Understanding these dynamics will empower you to make informed decisions, maximizing the efficiency and longevity of your tube exchanger while reducing operational costs and downtime.

Major Types of Tube Exchangers and Their Specific Industrial Uses

When selecting a tube exchanger for your industrial needs, understanding the various types available is crucial for optimizing performance. One of the most common types is the finned tube exchanger, which enhances heat transfer by increasing the surface area. This design is particularly beneficial in applications where space is limited, such as in HVAC systems or power plants. Another popular option is the double-pipe exchanger, known for its simplicity and ease of maintenance. This type is ideal for small-scale processes or operations where quick repairs are necessary.

Tip: Always consider the specific operational requirements, such as fluid types and temperature ranges, when choosing a tube exchanger. Assess the installation space and maintenance capabilities to ensure that the selected exchanger will function efficiently in your setting.

For more specialized applications, plate tube exchangers offer a compact design that excels in heat recovery processes. This type operates effectively with viscous fluids and in situations where high-pressure drop is a concern. They are commonly utilized in food processing and chemical industries, where cleanliness and efficiency are paramount.

Tip: Collaborate with suppliers to understand the performance specifications and options available for each type of tube exchanger. This collaboration can lead to tailored solutions that enhance your production efficiency.

Ultimate Guide to Selecting the Best Tube Exchanger for Your Industrial Needs

| Type of Tube Exchanger | Description | Common Industrial Applications | Efficiency Rating |

|---|---|---|---|

| Shell and Tube | Consists of a series of tubes, one set carries the hot fluid and the other the cold fluid. | Power plants, chemical processing, and oil refining. | High |

| Plate | Uses thin plates to transfer heat between two fluids. | Food industry, pharmaceuticals, and HVAC systems. | Very High |

| Air-Cooled | Utilizes air to cool or heat fluids without contact with water. | Power generation, petrochemical plants. | Moderate |

| Double-Pipe | Composed of two pipes, one inside the other; one fluid flows through the outer pipe, the other through the inner. | Small-scale heating or cooling processes in laboratories. | Low to Moderate |

| Spiral | Consists of two spiral channels where fluids flow in a counter-current fashion. | Food industry, wastewater treatment, and chemical process industries. | High |

Top Maintenance Tips to Enhance the Lifespan of Your Tube Exchanger

Maintaining the longevity of your tube exchanger is crucial for ensuring optimal performance and minimizing downtime in industrial operations. Regular inspections are essential; check for any signs of wear, corrosion, or fouling. Implement a routine cleaning schedule to remove debris and deposits that can impede heat transfer efficiency. Use appropriate cleaning agents that won't damage the materials of your tube exchanger, ensuring that the cleaning process aligns with manufacturer recommendations.

Another vital aspect of maintenance is monitoring operating conditions. Keeping an eye on pressures and temperatures will help detect any abnormal fluctuations that could indicate underlying issues. It’s also beneficial to conduct periodic thermal performance evaluations to assess the efficiency of heat transfer. Additionally, training your staff to recognize potential problems and understand basic troubleshooting techniques can significantly enhance the reliability of your tube exchanger system. Taking these proactive steps will not only extend the lifespan of the equipment but also reduce overall maintenance costs in the long run.