How to Identify the Best Plate-to-Plate Heat Exchanger Manufacturers for Optimal Performance

In the evolving landscape of industrial processing, the demand for efficient thermal management solutions has never been higher, making the selection of the right Plate to Plate Heat Exchanger critical for optimal performance. According to a recent market research report by Grand View Research, the global heat exchanger market is expected to reach USD 30.43 billion by 2025, with plate heat exchangers increasingly favored for their compact design and superior heat transfer efficiency. As industries ranging from food and beverage to chemical processing strive to enhance energy efficiency and reduce operational costs, identifying reputable manufacturers becomes paramount. This blog will provide a comprehensive checklist to help you navigate the myriad options available, ensuring you choose a supplier that delivers innovation, reliability, and performance in your Plate to Plate Heat Exchanger needs.

In the evolving landscape of industrial processing, the demand for efficient thermal management solutions has never been higher, making the selection of the right Plate to Plate Heat Exchanger critical for optimal performance. According to a recent market research report by Grand View Research, the global heat exchanger market is expected to reach USD 30.43 billion by 2025, with plate heat exchangers increasingly favored for their compact design and superior heat transfer efficiency. As industries ranging from food and beverage to chemical processing strive to enhance energy efficiency and reduce operational costs, identifying reputable manufacturers becomes paramount. This blog will provide a comprehensive checklist to help you navigate the myriad options available, ensuring you choose a supplier that delivers innovation, reliability, and performance in your Plate to Plate Heat Exchanger needs.

Factors to Consider When Choosing Plate-to-Plate Heat Exchangers for Industrial Applications

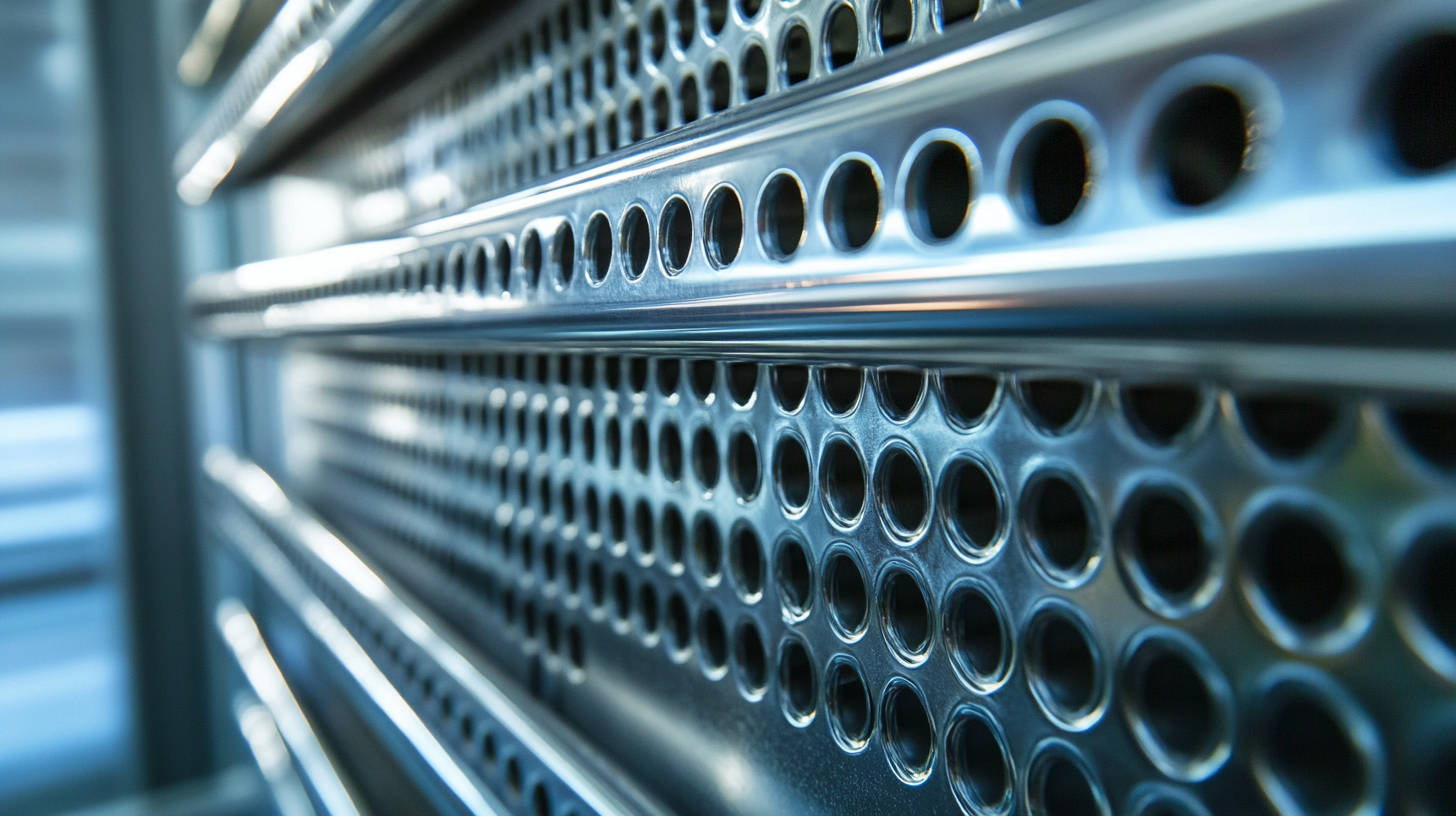

When selecting plate-to-plate heat exchangers for industrial applications, several crucial factors must be taken into account to ensure optimal performance. First and foremost, the material of construction is vital. Depending on the fluids being processed and the operating temperature and pressure conditions, materials like stainless steel, titanium, or polymers may be preferred to resist corrosion and wear while maintaining thermal efficiency.

Another significant consideration is the design of the heat exchanger. The plate configuration, surface area, and flow arrangement directly influence heat transfer efficiency and pressure drop. A well-designed heat exchanger optimizes these parameters to enhance thermal performance while minimizing energy consumption. Additionally, assess the manufacturer's reputation and experience in the industry, as established companies often provide superior engineering, support, and warranties, which can be invaluable in the long run. By focusing on material selection, design, and manufacturer reliability, you can identify the best heat exchanger that meets your specific operational needs.

How to Identify the Best Plate-to-Plate Heat Exchanger Manufacturers for Optimal Performance

| Manufacturer Type | Heat Exchanger Material | Efficiency Rating | Temperature Range (°C) | Application Areas |

|---|---|---|---|---|

| Standard Manufacturer | Stainless Steel | 85% | -10 to 150 | Food & Beverage |

| High-efficiency Manufacturer | Titanium | 95% | -40 to 200 | Chemical Processing |

| Custom Manufacturer | Copper-Nickel | 90% | 0 to 180 | Marine Applications |

| Premium Manufacturer | Alloy Steel | 92% | -20 to 250 | Oil & Gas |

Comparison of Various Plate Materials and Their Thermal Conductivity Properties

When evaluating plate-to-plate heat exchangers, one of the most critical factors is the material composition of the plates, as it directly influences thermal conductivity and overall performance. Stainless steel, for example, has a thermal conductivity of approximately 15 W/m·K, making it a popular choice for a variety of applications due to its excellent corrosion resistance and mechanical stability. In contrast, titanium, with a thermal conductivity of around 22 W/m·K, is favored for highly corrosive environments, despite its higher cost.

Additionally, newer materials such as graphene-coated plates are emerging in the market, boasting thermal conductivities as high as 2000 W/m·K. While still in the experimental stages, their application could revolutionize heat exchanger technology by significantly enhancing efficiency in heat transfer processes. Manufacturers are increasingly recognizing the importance of selecting the right materials not only to optimize performance but also to extend the lifespan of equipment, thus reducing long-term operational costs. According to a recent Frost & Sullivan report, the demand for high-performance materials in heat exchangers is projected to grow by 6% annually through 2025, underscoring the need for manufacturers to stay abreast of advancements in material science.

Application Suitability: Matching Heat Exchangers to Specific Industry Needs

When selecting a plate-to-plate heat exchanger, understanding its application suitability is paramount. Each industry has unique thermal requirements and fluid characteristics, which means that not all heat exchangers will perform optimally in every environment.

For instance, in the food and beverage sector, heat exchangers must comply with stringent hygiene standards while efficiently managing heat transfer. This necessitates manufacturers that specialize in sanitary designs and materials resistant to corrosive agents.

In the chemical industry, the variety of fluids and temperatures can drastically influence the choice of heat exchanger. It’s essential to partner with manufacturers who are experienced in designing solutions tailored to specific processes, whether that involves handling viscous fluids or operating under high pressure.

Furthermore, factors such as thermal efficiency, ease of maintenance, and lifetime performance should guide the decision-making process. By focusing on these industry-specific needs, you can ensure that the heat exchanger not only fits the application but also enhances overall operational efficiency.

Understanding Efficiency Ratings and Performance Metrics for Heat Exchangers

When searching for the best plate-to-plate heat exchanger manufacturers, understanding efficiency ratings and performance metrics is crucial for achieving optimal performance. Efficiency ratings provide insights into how effectively a heat exchanger transfers heat.

Common metrics, such as the Overall Heat Transfer Coefficient (U-value) and the Temperature Difference (ΔT), help to evaluate the exchanger's effectiveness under different operating conditions. A higher U-value typically indicates better heat transfer capabilities, while the ΔT reflects the temperature change between the hot and cold fluids. Manufacturers often provide these ratings in their product specifications, allowing engineers to compare units on a standardized basis.

When searching for the best plate-to-plate heat exchanger manufacturers, understanding efficiency ratings and performance metrics is crucial for achieving optimal performance. Efficiency ratings provide insights into how effectively a heat exchanger transfers heat.

Common metrics, such as the Overall Heat Transfer Coefficient (U-value) and the Temperature Difference (ΔT), help to evaluate the exchanger's effectiveness under different operating conditions. A higher U-value typically indicates better heat transfer capabilities, while the ΔT reflects the temperature change between the hot and cold fluids. Manufacturers often provide these ratings in their product specifications, allowing engineers to compare units on a standardized basis.

Additionally, performance metrics like pressure drop and fouling characteristics are essential to consider. A heat exchanger with a low pressure drop minimizes the energy required for fluid circulation, enhancing overall system efficiency. Furthermore, understanding fouling resistance is vital, as it influences maintenance requirements and long-term performance. Choosing a manufacturer that offers data on these factors is advantageous; it ensures that you can select the right heat exchanger for your specific application while maintaining optimal energy use and operational longevity. Hence, a thorough evaluation of efficiency ratings and performance metrics is key to selecting the best plate-to-plate heat exchangers suited to your needs.

Key Manufacturers in the Market: Innovations and Technological Advancements

When searching for the best plate-to-plate heat exchanger manufacturers, it's crucial to focus on those leading the market with noteworthy innovations and technological advancements. Reports from industry experts indicate that the global market for heat exchangers is expected to reach USD 25 billion by 2026, with significant contributions from manufacturers who prioritize efficiency and sustainability. Key players such as Alfa Laval and GEA Group are at the forefront, implementing cutting-edge technologies like digital monitoring and enhanced thermal performance, which ensure optimal performance in various applications.

Tips for identifying top manufacturers include evaluating their product certifications and performance metrics. For instance, a study by ResearchAndMarkets has shown that companies producing heat exchangers with higher thermal efficiency standards not only reduce operational costs but also minimize environmental impact. Additionally, consider manufacturers that invest in R&D – firms that allocate at least 7% of their revenue to innovation often outpace their competitors in reliability and customer satisfaction.

Furthermore, keep an eye on the latest technological developments, such as the integration of advanced materials and automation in manufacturing processes. According to a report by MarketsandMarkets, the use of stainless steel and specialized alloys has revolutionized the durability and lifespan of heat exchangers. Engaging with manufacturers who are proactive in adopting these advancements can lead to significant long-term benefits for your operations.