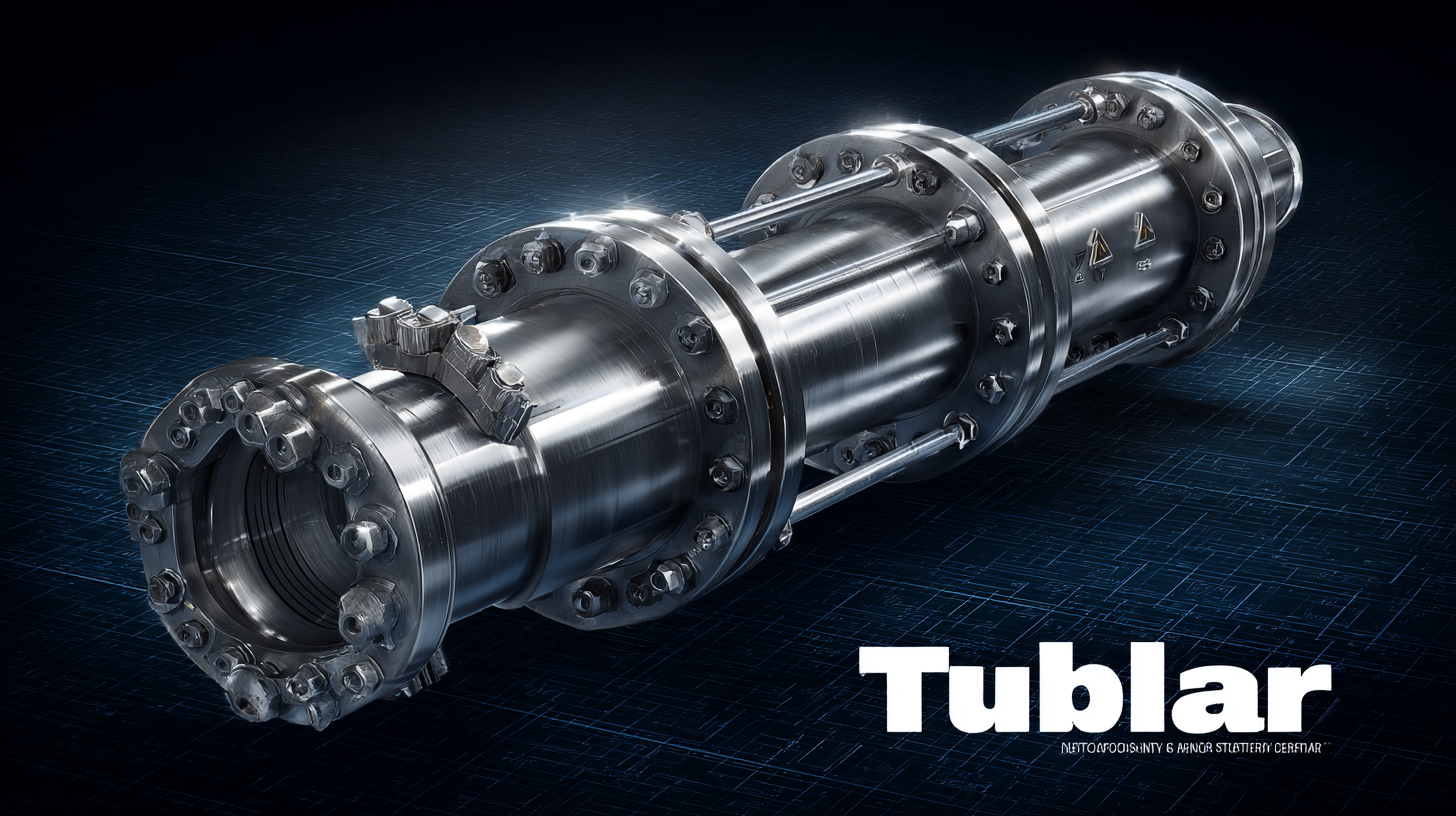

Understanding Industry Standards for the Best Tubular Heat Exchanger: What Sets It Apart?

In the realm of thermal management technologies, Tubular Heat Exchangers have emerged as a critical component across various industries, from petrochemicals to food processing. According to a report by Markets and Markets, the global heat exchanger market is projected to reach $18.3 billion by 2025, with tubular designs increasingly favored for their efficiency, durability, and adaptability in extreme conditions.

Understanding the industry standards that govern these systems is essential for selecting the best tubular heat exchanger for specific applications. Factors such as material selection, design specifications, and performance ratings play a pivotal role in ensuring reliability and efficacy. This blog aims to dissect the nuances of tubular heat exchangers, exploring what truly sets them apart in a competitive landscape, thereby empowering professionals to make informed decisions that enhance operational efficiency and sustainability.

Key Characteristics of High-Quality Tubular Heat Exchangers: A Comprehensive Overview

When it comes to tubular heat exchangers, understanding the key characteristics that define high quality is essential for effective industrial application. One of the most critical features is the material used in construction. Top-tier tubular heat exchangers often utilize alloys that not only enhance thermal conductivity but also resist corrosion and wear. This durability ensures longevity, minimizing downtime and maintenance costs, which is particularly valuable in industries dealing with harsh environments.

Another significant characteristic is the design of the tubes. High-quality tubular heat exchangers typically feature optimized tube arrangements that improve heat transfer efficiency. Enhanced designs, such as helically corrugated tubes, increase surface area contact, promoting better thermal exchange between fluids. Additionally, factors such as ease of cleaning and the capability to handle varying flow rates are important. These attributes contribute to optimal performance in diverse operational conditions, ensuring that these heat exchangers meet industrial standards and regulatory requirements effectively.

The Role of Industry Standards in Tubular Heat Exchanger Manufacturing

When it comes to manufacturing tubular heat exchangers, adherence to industry standards is paramount. These standards provide a framework that ensures safety, efficiency, and reliability in heat exchange processes. Organizations such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) outline specific criteria regarding materials, design, testing, and maintenance. By complying with these guidelines, manufacturers can enhance the quality of their products and ensure they meet the operational demands of various industries including power generation, chemical processing, and HVAC.

Moreover, industry standards play a crucial role in fostering trust between manufacturers and their clients. When a tubular heat exchanger is built following recognized standards, it allows clients to confidently assess its performance and longevity. This transparency not only aids in reducing risks associated with equipment failure but also enhances the overall efficiency of thermal systems. Consequently, manufacturers who prioritize these standards distinguish themselves in a competitive market, highlighting their commitment to quality and reliability in every unit produced.

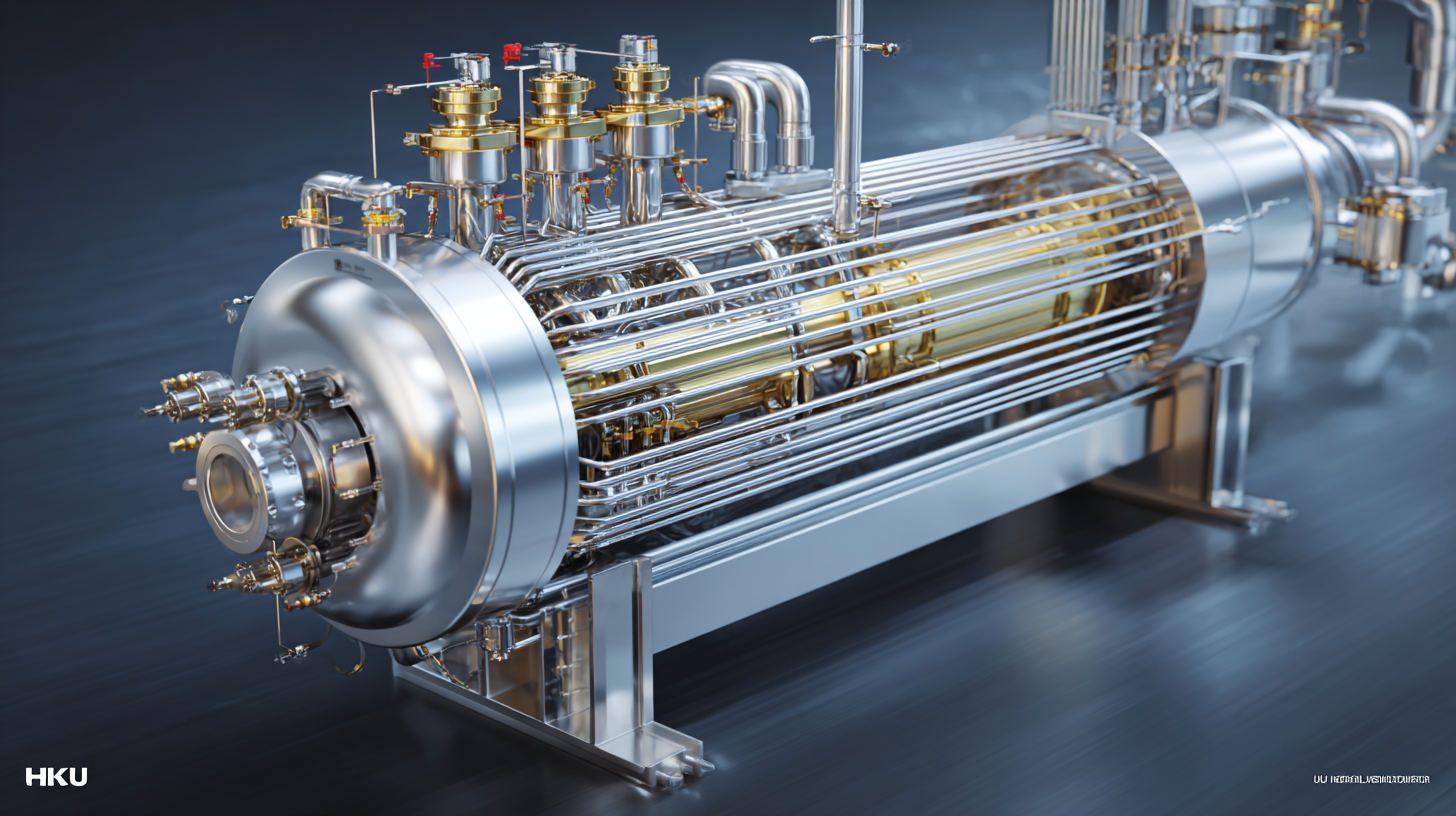

Innovative Technologies Enhancing Tubular Heat Exchanger Performance

Innovative technologies are revolutionizing the performance of tubular heat exchangers, making them more efficient and reliable than ever before. Recent industry reports indicate that advancements in materials, design, and digital monitoring are key drivers of improved heat transfer efficiency. For example, the incorporation of enhanced surface materials has been shown to increase heat transfer rates by as much as 30%, leading to significant energy savings in various applications, from chemical processing to power generation.

When considering a tubular heat exchanger, it's crucial to prioritize key factors that contribute to enhanced performance. One tip is to look for exchangers that employ advanced computational fluid dynamics (CFD) simulations during the design phase. This technology allows for the optimization of flow patterns and thermal performance, resulting in systems that operate effectively under varying conditions. Additionally, implementing IoT sensors can provide real-time data on performance metrics, enabling predictive maintenance and minimizing downtime.

Another innovative technology to watch is the development of modular designs, which allow for easier upgrades and retrofitting. These modular systems can accommodate changing process requirements without necessitating a complete overhaul. This adaptability can help facilities keep pace with industry changes and operational demands while maintaining high efficiency and reliability in thermal management systems.

Understanding Industry Standards for the Best Tubular Heat Exchanger: What Sets It Apart? - Innovative Technologies Enhancing Tubular Heat Exchanger Performance

| Parameter | Standard Value | Description |

|---|---|---|

| Heat Transfer Efficiency (U) | 300-600 W/m²K | The efficiency of heat transfer in a tubular heat exchanger. |

| Pressure Drop | 10-30 kPa | The pressure loss experienced by the fluid passing through the exchanger. |

| Material of Construction | Stainless Steel, Copper Alloys | Common materials used for durability and corrosion resistance. |

| Operating Temperature Range | -40°C to 400°C | The temperature range in which the heat exchanger effectively operates. |

| Surface Area (A) | 5-100 m² | The total surface area available for heat exchange. |

| Flow Arrangement | Counterflow, Parallel Flow | The configuration of the fluid flow paths within the heat exchanger. |

Comparative Advantages: Tubular vs. Other Heat Exchanger Types

When discussing heat exchangers, tubular heat exchangers stand out due to their unique design and operational advantages. Unlike other types, such as plate or finned-tube heat exchangers, tubular heat exchangers consist of a series of tubes, allowing for efficient heat transfer between fluids. Their simple construction translates to ease of maintenance and cleaning, reducing downtime in industrial applications. Furthermore, the cylindrical shape enables them to withstand high pressure and temperature variations, making them suitable for demanding environments in industries like chemical processing and power generation.

When discussing heat exchangers, tubular heat exchangers stand out due to their unique design and operational advantages. Unlike other types, such as plate or finned-tube heat exchangers, tubular heat exchangers consist of a series of tubes, allowing for efficient heat transfer between fluids. Their simple construction translates to ease of maintenance and cleaning, reducing downtime in industrial applications. Furthermore, the cylindrical shape enables them to withstand high pressure and temperature variations, making them suitable for demanding environments in industries like chemical processing and power generation.

Comparatively, tubular heat exchangers offer superior durability and versatility over their counterparts. For instance, while plate heat exchangers are advantageous in applications requiring compact designs, they may struggle with fouling, necessitating frequent maintenance. In contrast, tubular designs facilitate easier access for cleaning, thereby enhancing longevity and service intervals. Additionally, tubular heat exchangers are capable of handling a wider range of fluid types, including non-Newtonian fluids, which might be more challenging for plate and shell-and-tube exchangers. By incorporating these advantages, tubular heat exchangers not only ensure efficient thermal performance but also contribute to overall operational efficiency in various industrial processes.

Choosing the Right Tubular Heat Exchanger for Your Industry Needs

When selecting a tubular heat exchanger for your specific industry needs, it is essential to consider various factors that impact performance and efficiency. One critical aspect is the design and material composition of the heat exchanger. Industries such as oil and gas, food processing, and pharmaceuticals often require heat exchangers that can withstand high pressures and corrosive environments. Choosing a unit made from materials such as stainless steel or specialized alloys can enhance durability and extend operational life.

Moreover, understanding the thermal and hydraulic performance requirements is vital. Tubular heat exchangers come in various configurations, each offering distinct advantages for different applications. For instance, a multi-tube design may be more effective in transferring heat in heavy-duty applications compared to single-tube systems. Evaluating flow arrangement—whether it’s counterflow, parallel flow, or crossflow—can significantly influence thermal efficiency. By assessing these factors, industries can make informed decisions that optimize their heat transfer processes and contribute to overall productivity.

Performance Comparison of Tubular Heat Exchangers

This chart presents a comparison of the thermal efficiency and pressure drop of different types of tubular heat exchangers, illustrating their effectiveness for various industrial applications.