Innovative Solutions for Maximizing Efficiency with the Best Spiral Heat Exchanger

In today's fast-paced industrial landscape, maximizing efficiency is paramount for companies aiming to reduce operational costs and improve sustainability. The Spiral Heat Exchanger stands out as an innovative solution that can significantly enhance heat transfer efficiency. According to a report by Grand View Research, the global heat exchanger market is projected to reach $24.57 billion by 2025, driven by the increasing demand for energy-efficient technologies across various sectors, including HVAC and chemical manufacturing. The unique design of Spiral Heat Exchangers, which allows for a compact footprint and enhanced thermal performance, positions them as a critical component in optimizing energy usage. As industries seek to implement more effective cooling and heating strategies, understanding the benefits and applications of Spiral Heat Exchangers becomes essential for driving efficiency and achieving sustainability goals.

Revolutionizing Heat Transfer: The Role of Spiral Heat Exchangers in Various Industries

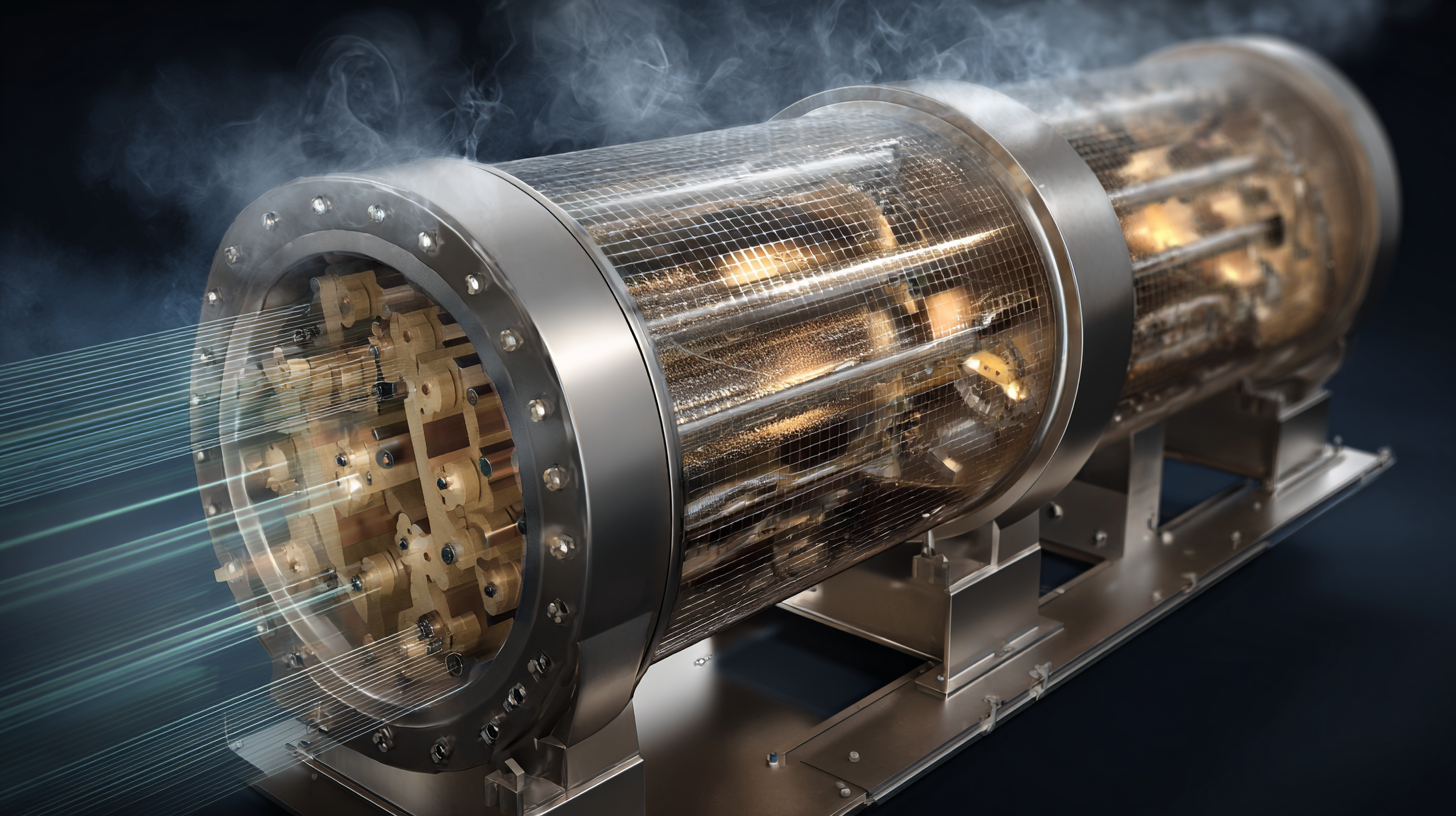

In various industries, the significance of efficient heat transfer cannot be overstated. Spiral heat exchangers have emerged as a revolutionary solution, addressing the ever-present demand for energy efficiency and process optimization. Their unique design, featuring a continuous spiral flow path, allows for higher heat transfer rates in a compact footprint, making them ideal for industries ranging from chemical processing to food production. The reduced pressure drop across the unit not only enhances performance but also contributes to lower energy costs, which is a critical factor in today's competitive market.

Furthermore, spiral heat exchangers excel in applications that involve viscous fluids or when handling liquid-liquid or gas-liquid processes. Their ability to maintain uniform flow and prevent fouling ensures consistent heat transfer performance over time, a major advantage in maintaining operational reliability. As industries increasingly focus on sustainability and resource conservation, the adoption of spiral heat exchangers continues to grow, showcasing their integral role in modern heat transfer technologies and underscoring their potential to propel efficiency and innovation across diverse sectors.

Overcoming Common Challenges: Issues Faced by Spiral Heat Exchanger Users

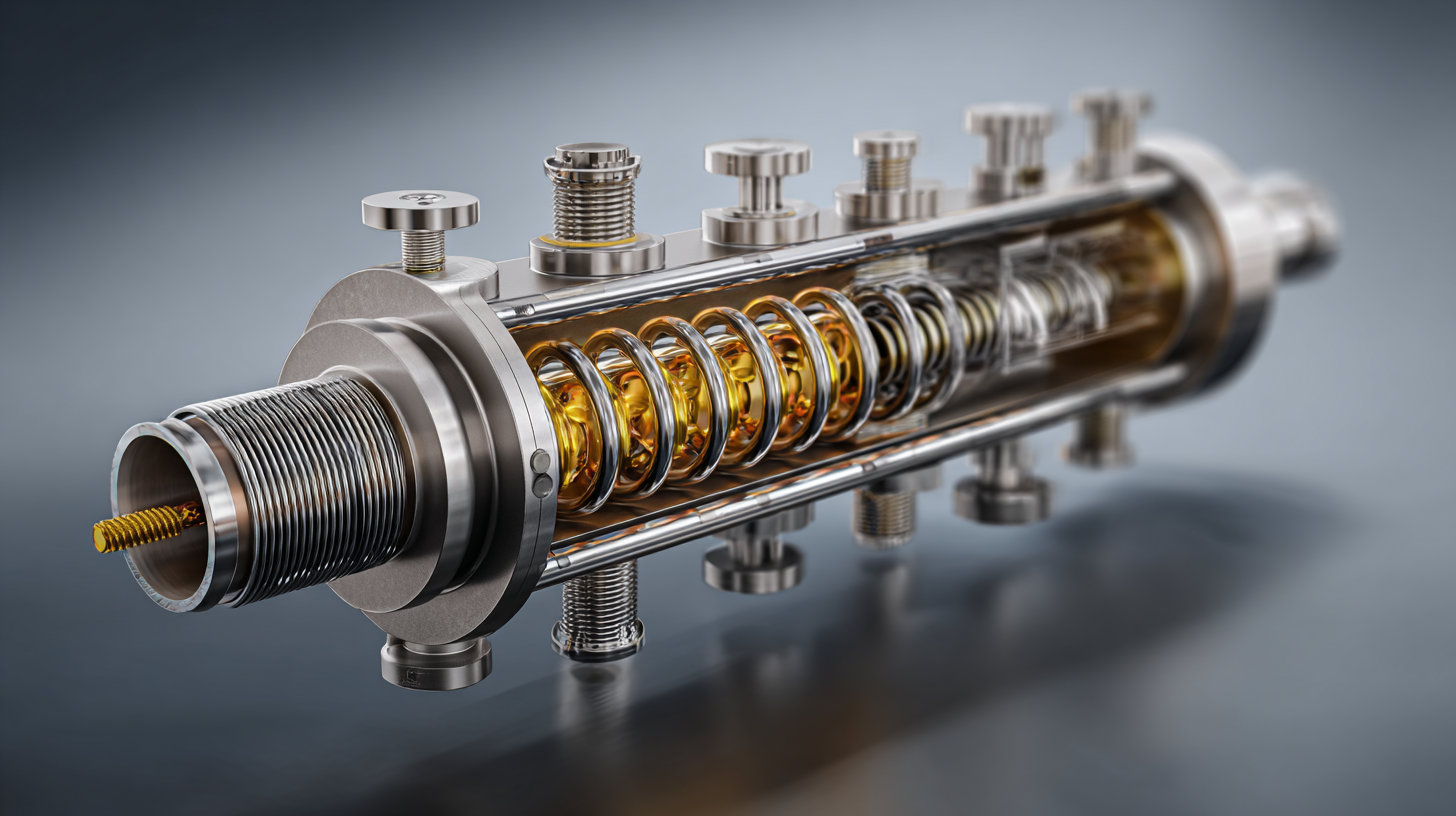

Spiral heat exchangers are lauded for their compact design and efficient heat transfer capabilities, but users often encounter common challenges that can hinder optimal performance. One major issue is fouling, which leads to a decrease in heat exchange efficiency over time. The design of spiral heat exchangers can sometimes exacerbate this problem, as their narrow flow passages can accumulate deposits that are difficult to remove. Regular maintenance and effective cleaning methods are crucial for minimizing fouling and ensuring the longevity of the equipment.

Another challenge faced by users is pressure drop, which can impact the overall system efficiency. Spiral heat exchangers typically operate at lower pressure drops than traditional shell-and-tube designs, but increases in flow rates or incorrect sizing can result in unexpected pressure losses. Properly designed systems and accurate sizing based on comprehensive thermal and hydraulic calculations can help mitigate these issues. By addressing these challenges proactively, users can maximize the efficiency of their spiral heat exchangers, leading to better overall performance and cost savings.

Case Studies: Successful Applications of Spiral Heat Exchangers in Real-World Scenarios

Spiral heat exchangers have increasingly proven their efficiency in various industrial applications, showcasing their unique ability to handle challenging conditions. A prime example is in the chemical processing industry, where these exchangers excel in facilitating heat transfer between corrosive fluids. In one case study, a chemical plant improved production efficiency by 30% after replacing traditional heat exchangers with spiral designs, allowing for a more compact footprint while handling aggressive fluids effectively.

Another noteworthy application of spiral heat exchangers is in the food processing sector, where hygiene and thermal performance are crucial. A dairy company utilized spiral heat exchangers for pasteurization, significantly reducing energy consumption and increasing output. By integrating these systems, they achieved consistent temperature maintenance while preserving product quality.

**Tips for Implementation:** When considering spiral heat exchangers, ensure to assess the specific thermal dynamics of your process. Opt for manufacturers that offer customization for unique applications. Regular maintenance checks can further enhance efficiency and longevity, ensuring continued performance benefits in real-world operations.

Innovative Solutions for Maximizing Efficiency with the Best Spiral Heat Exchanger - Case Studies: Successful Applications of Spiral Heat Exchangers in Real-World Scenarios

| Application Area | Industry | Heat Transfer Area (m²) | Flow Rate (m³/h) | Temperature Difference (°C) | Efficiency Improvement (%) |

|---|---|---|---|---|---|

| Waste Heat Recovery | Chemical Manufacturing | 250 | 100 | 50 | 30 |

| Process Cooling | Food and Beverage | 180 | 75 | 40 | 25 |

| Fluid Heating | Petroleum Refining | 300 | 120 | 60 | 35 |

| Heat Recovery for District Heating | Energy Sector | 400 | 200 | 55 | 40 |

| Heat Exchanger for HVAC Systems | Construction | 150 | 50 | 45 | 20 |

Enhancing Process Efficiency: How Spiral Heat Exchangers Address Industry-Specific Needs

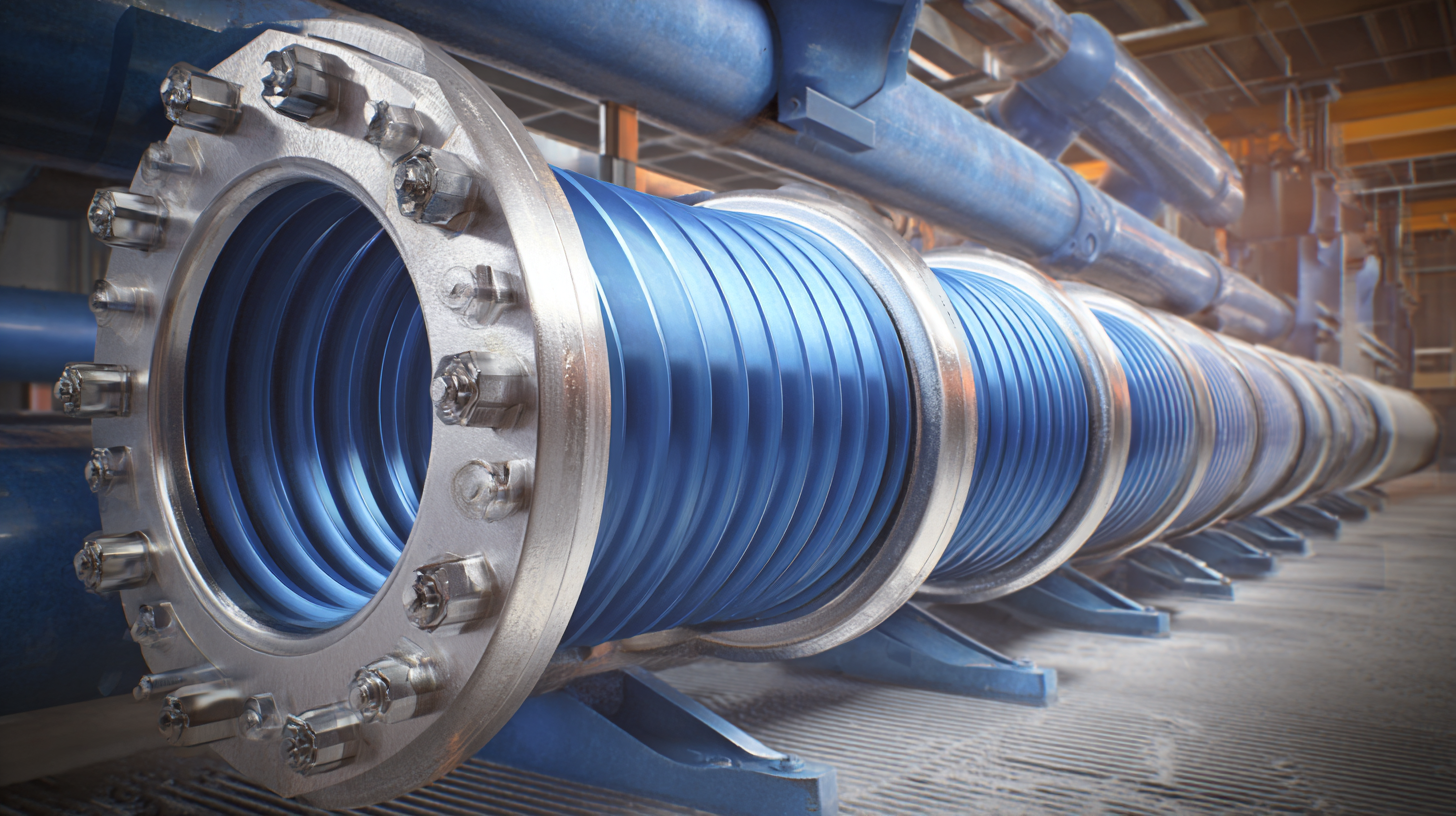

Spiral heat exchangers have emerged as a pivotal technology in enhancing process efficiency across various industrial sectors. Their unique design allows for compact heat transfer, making them capable of handling different types of fluids with superior thermal performance. According to industry reports, spiral heat exchangers can achieve temperature differentials that are typically 20-30% greater than that of traditional shell-and-tube models, particularly in applications involving viscous fluids and slurries. This efficiency not only reduces energy costs but also minimizes the footprint of heat exchange systems, addressing space constraints found within many manufacturing settings.

Recent studies highlight the advancements in spiral tube technologies, particularly the novel oval-pit spiral tube design, which demonstrates improved secondary flow characteristics and heat transfer rates. These innovations are essential in sectors such as chemical processing and renewable energy, where maximizing heat recovery can lead to significant reductions in operational costs. Additionally, with the increasing focus on decarbonization, the ability of spiral heat exchangers to enhance thermal efficiency positions them as a critical component in supporting industry-wide sustainability goals, thereby aligning with initiatives like the recent $38 million funding opportunity announced by the Industrial Efficiency and Decarbonization Office.

Future Trends: Innovations Shaping the Development of Spiral Heat Exchangers

The future of spiral heat exchangers is being shaped by a number of innovative trends that promise to enhance efficiency and sustainability across various industries. According to a report by MarketsandMarkets, the heat exchanger market is projected to reach USD $28.5 billion by 2026, growing at a CAGR of 8.5% from 2021. This growth underscores the increasing demand for more efficient heat transfer solutions in sectors such as chemicals, petrochemicals, and energy production.

One of the key innovations driving this sector is the integration of advanced materials and design methodologies. The use of corrosion-resistant materials not only extends the lifespan of spiral heat exchangers but also improves energy transfer efficiency. Additionally, computational fluid dynamics (CFD) modeling is revolutionizing the design process, enabling engineers to optimize flow patterns and reduce pressure drops. A study from the Journal of Thermal Science and Engineering Applications highlights that such technological advancements can improve heat transfer rates by up to 30%, demonstrating the tangible benefits of these innovations.

Moreover, the rise of sustainable practices is pushing manufacturers to adopt innovative solutions like modular spiral heat exchangers. These systems can be more easily scaled or modified based on changing operational needs, which aligns with the evolving regulatory landscape favoring energy efficiency. Reports indicate that modular designs can lead to installation cost savings of roughly 15% while also enhancing thermal performance, emphasizing the dual benefit of innovation in efficiency and adaptability.