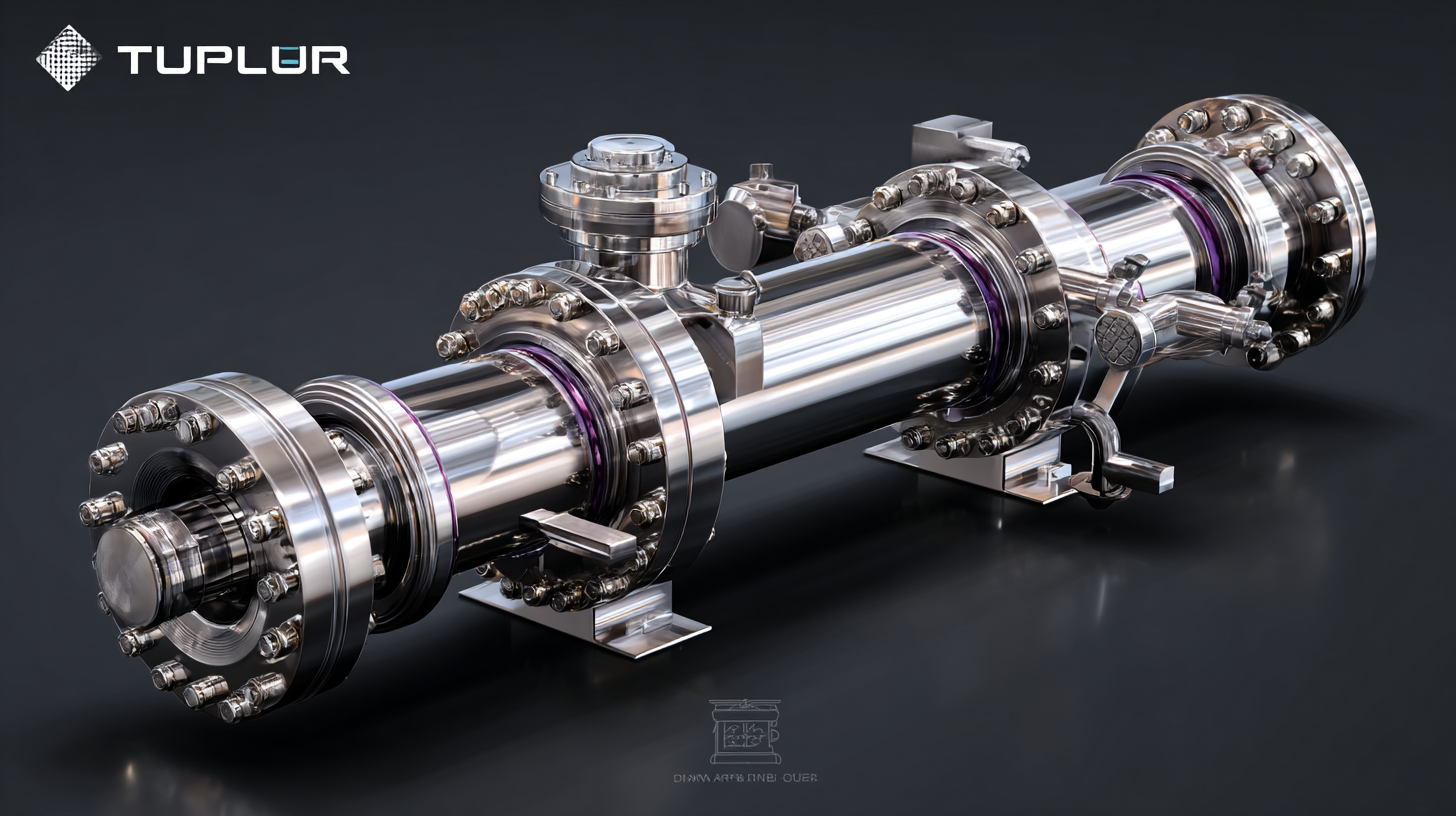

Crafted Precision from China Powering Global Industries with the Best Tubular Heat Exchanger

In the realm of industrial heat transfer solutions, the significance of Tubular Heat Exchangers cannot be overstated. These sophisticated devices are essential for efficient thermal management across various sectors, including oil and gas, food processing, and chemical manufacturing. According to a report by MarketsandMarkets, the global heat exchanger market is projected to reach $20.6 billion by 2025, growing at a CAGR of 8.5% from 2020, driven by the increasing demand for energy-efficient solutions.

China has emerged as a pivotal player in this industry, leveraging its advanced manufacturing capabilities to deliver high-quality Tubular Heat Exchangers that cater to the needs of global industries. The precision engineering involved in crafting these exchangers not only enhances performance but also contributes significantly to sustainability goals, underlining their importance in both current and future industrial applications.

The Rise of Tubular Heat Exchangers: A Global Perspective

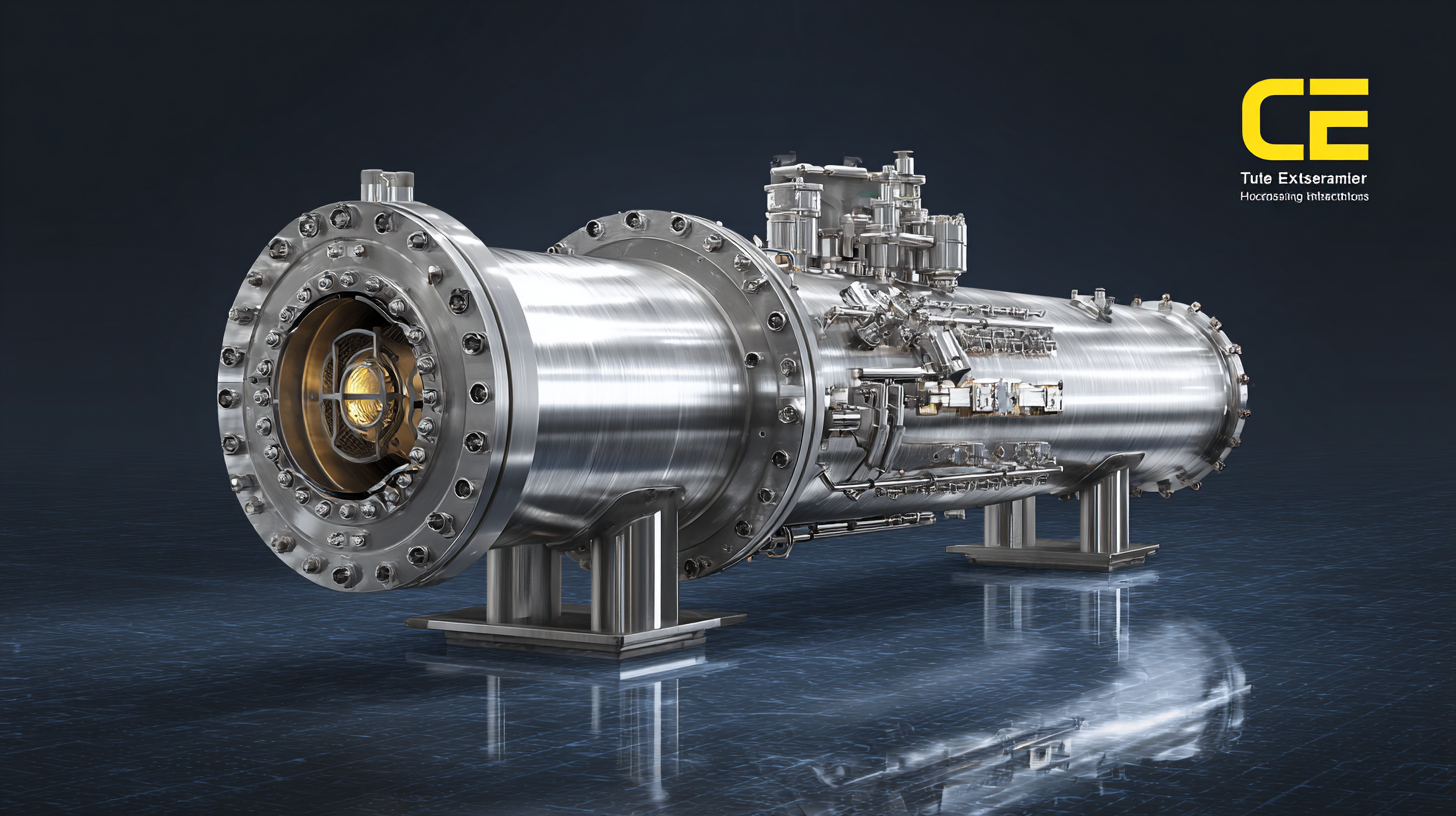

The global industrial landscape has seen a significant shift with the rise of tubular heat exchangers, which are becoming increasingly vital across various sectors. Their innovative design and efficient heat transfer capabilities make them a preferred choice for industries ranging from oil and gas to food processing. As companies seek to improve energy efficiency and reduce operational costs, tubular heat exchangers have emerged as a reliable solution that meets these pressing demands.

China has swiftly positioned itself as a leader in manufacturing high-quality tubular heat exchangers, powering industries worldwide with meticulously crafted products. The combination of advanced technology and skilled craftsmanship has allowed Chinese manufacturers to meet the rigorous standards expected in global markets. As industries continue to evolve and prioritize sustainability, the role of these heat exchangers in enhancing thermal management is more crucial than ever. Their versatility and performance ensure that they are not just an option but a necessity for future-focused enterprises aiming to stay competitive.

Chinese Manufacturing Excellence: The Backbone of Quality Heat Exchangers

Chinese manufacturing has long been recognized as a powerhouse of production, but it's the country's commitment to excellence that truly shines in the realm of heat exchangers. With advanced technologies and a skilled workforce, China excels at crafting tubular heat exchangers that meet stringent global standards. These state-of-the-art components are essential in a variety of industries, including petrochemical, HVAC, and food processing, where efficiency and reliability are paramount.

The meticulous craftsmanship found in Chinese manufactured heat exchangers not only enhances performance but also provides significant cost advantages for businesses worldwide. By leveraging innovation and quality control measures, manufacturers ensure that each unit is designed to optimize thermal efficiency and longevity. This dedication to excellence transforms Chinese products into sought-after solutions for global industries, showcasing how quality and precision from China can power the future of energy and resource management across the globe.

Global Tubular Heat Exchanger Production by Region (2023)

This chart illustrates the production volume of tubular heat exchangers in different regions globally. The data represents the estimated output in thousands of units, showcasing the manufacturing excellence of various regions.

Innovative Technologies Driving Efficiency in Tubular Heat Exchangers

In the competitive landscape of industrial thermal management, tubular heat exchangers have emerged as critical components, significantly enhancing energy efficiency across various sectors. Innovative technologies in tubular heat exchangers are setting new benchmarks for performance and sustainability. According to a report by the Global Heat Exchanger Market, the demand for these devices is expected to grow at a CAGR of around 6.1% from 2021 to 2026, driven by increasing energy efficiency regulations and a push toward sustainable industrial practices.

Recent advancements, such as the integration of smart sensors and advanced materials, are revolutionizing the functionality of tubular heat exchangers. These innovations not only improve heat transfer efficiency but also ensure durability and lower maintenance costs. For instance, a study by the International Energy Agency (IEA) highlighted that optimizing heat exchanger designs could lead to energy savings of up to 30% in various industrial applications. The incorporation of computational fluid dynamics (CFD) in the design phase allows manufacturers to tailor solutions that meet the unique requirements of different industries, thereby maximizing operational efficiency.

As industries across the globe continue to prioritize resource efficiency and sustainability, tubular heat exchangers stand at the forefront of this transformation. By leveraging cutting-edge technologies, manufacturers are not only meeting energy demands but also contributing to a greener future—making tubular heat exchangers a pivotal element in the quest for industrial excellence.

Meeting Global Standards: China’s Commitment to Quality and Reliability

In today's competitive global landscape, China has emerged as a formidable player in manufacturing, particularly in creating high-quality tubular heat exchangers. These devices are crucial for various industries, and China's commitment to excellence ensures that they meet stringent global standards. By integrating advanced technology with skilled craftsmanship, Chinese manufacturers deliver products that not only perform efficiently but also adhere to international safety and durability benchmarks.

In today's competitive global landscape, China has emerged as a formidable player in manufacturing, particularly in creating high-quality tubular heat exchangers. These devices are crucial for various industries, and China's commitment to excellence ensures that they meet stringent global standards. By integrating advanced technology with skilled craftsmanship, Chinese manufacturers deliver products that not only perform efficiently but also adhere to international safety and durability benchmarks.

Tip: When choosing a tubular heat exchanger, it's essential to consider the manufacturer's certifications and compliance with global standards. Look for products that showcase ISO certifications or adherence to ASME standards, ensuring that you invest in reliable and high-performance equipment.

Moreover, China's ongoing investments in innovation and quality control further bolster its position in the global market. By leveraging state-of-the-art manufacturing processes, these companies guarantee precision and durability in their products. Consumers benefit from this commitment, as they receive heat exchangers that are not only effective but also economical in the long run.

Tip: Regular maintenance and inspection of your heat exchanger can prolong its lifespan and enhance efficiency. Establish a routine checkup schedule, and always consult industry experts for best practices to achieve optimal performance.

Harnessing Sustainability: The Future of Heat Exchanger Production in China

China's tubular heat exchanger production is undergoing a transformative evolution, centering on sustainability and environmental responsibility. As industries worldwide prioritize eco-friendly practices, Chinese manufacturers are stepping up to lead the charge. By implementing advanced manufacturing techniques and utilizing sustainable materials, they are not just meeting the rising global demand for efficiency but also minimizing their ecological footprint. This shift not only benefits manufacturers but also positions China as a pivotal player in the sustainable industrial landscape.

Moreover, the future of heat exchanger production in China is brightened by innovation that harmonizes functionality with eco-consciousness. Embracing renewable energy sources and reducing waste during the manufacturing process is paving the way for cutting-edge products that offer enhanced performance while conserving natural resources. As global industries seek robust solutions to tackle climate change, China's dedication to sustainability in heat exchanger production is not only a market advantage but also a commitment to a greener, more efficient future. This sustainability-focused approach is revolutionizing the industry and setting new standards for global manufacturing efficiency and responsibility.

Crafted Precision from China Powering Global Industries with the Best Tubular Heat Exchanger

| Industry | Application | Material Used | Sustainability Features | Efficiency Rating |

|---|---|---|---|---|

| Oil & Gas | Crude Oil Processing | Carbon Steel | Low Emission | 95% |

| Chemical Processing | Heat Recovery | Stainless Steel | Recyclable Materials | 90% |

| HVAC | Cooling Systems | Copper | Energy Efficient Design | 93% |

| Food & Beverage | Pasteurization | Titanium | Low Energy Consumption | 92% |