Revolutionizing Energy Efficiency: The Future of Best Spiral Heat Exchangers

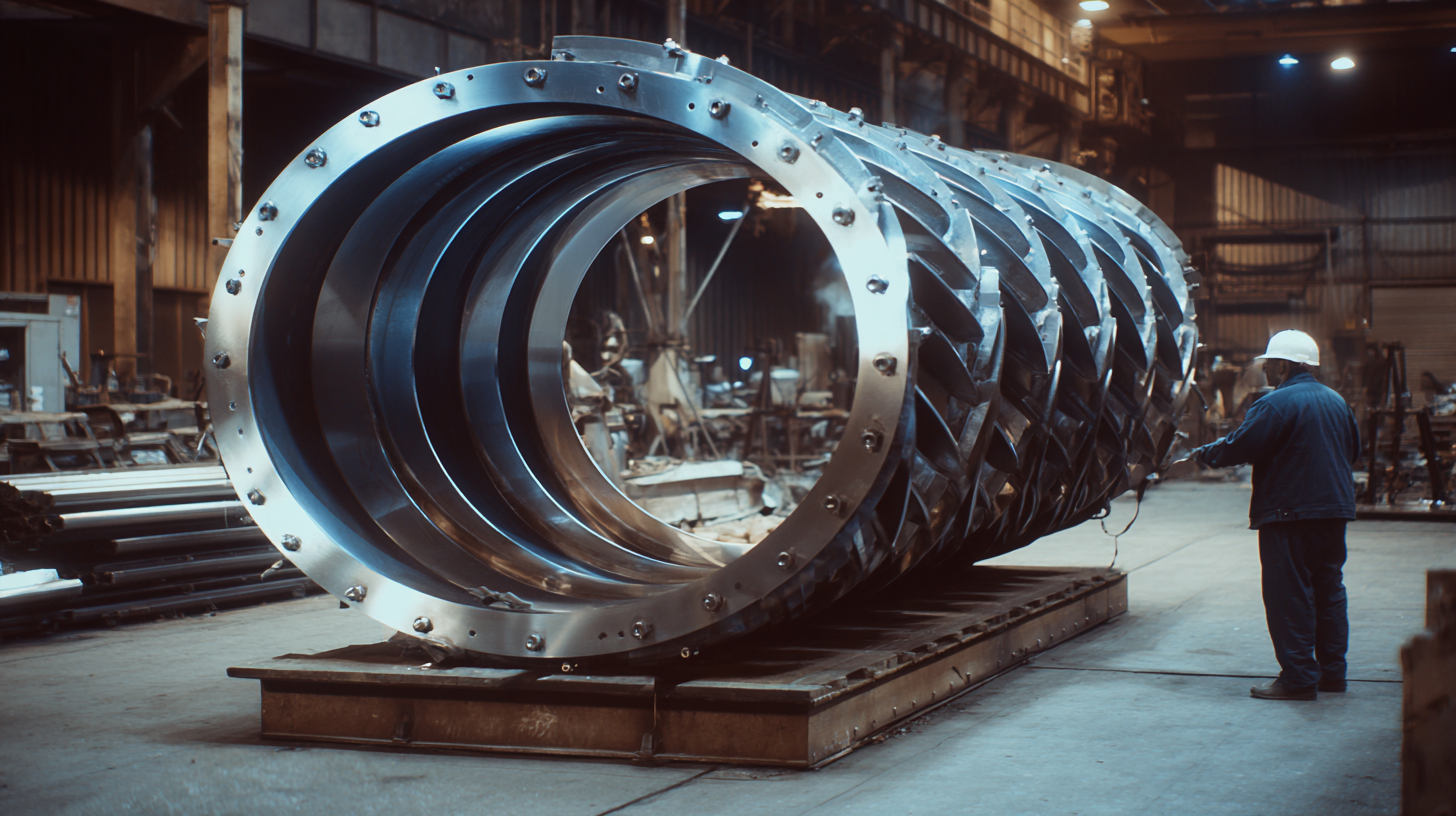

The demand for energy efficiency has never been more critical, as industries worldwide strive to reduce costs and minimize environmental impact. According to a report by the International Energy Agency (IEA), energy efficiency improvements could lead to a reduction of global energy consumption by up to 30% by 2030. In this context, the Spiral Heat Exchanger stands out as a transformative technology. Offering superior thermal performance and a compact design, Spiral Heat Exchangers are revolutionizing processes in sectors such as chemical, petrochemical, and food processing.

With their unique configuration, these devices enhance heat transfer efficiency while occupying less space compared to traditional heat exchangers, thus promising significant savings on energy and operational costs. As we delve deeper into the future of energy-efficient technologies, understanding the detailed technical parameters and applications of Spiral Heat Exchangers will be essential to harness their full potential.

The Rise of Spiral Heat Exchangers: A Game Changer in Energy Efficiency

The rise of spiral heat exchangers marks a transformative shift in the pursuit of energy efficiency across various industries. According to a recent report by Research and Markets, the global heat exchanger market is projected to reach USD 23.9 billion by 2025, driven by the increasing demand for energy-efficient solutions. Spiral heat exchangers, in particular, are gaining traction due to their compact design and enhanced thermal performance. They utilize a unique spiral configuration that optimizes fluid dynamics, resulting in significantly lower operational costs and improved heat transfer efficiency.

In sectors such as chemical processing and HVAC, spiral heat exchangers are proving to be game changers. A study published by the International Journal of Energy Research indicated that these exchangers can improve thermal efficiency by up to 30% compared to traditional shell-and-tube designs. Moreover, their ability to handle high-pressure and high-viscosity fluids makes them ideal for a variety of applications. As industries continue to prioritize sustainability and energy conservation, the adoption of spiral heat exchangers is set to accelerate, paving the way for a more efficient future.

Revolutionizing Energy Efficiency: The Future of Best Spiral Heat Exchangers

| Parameter | Value | Unit |

|---|---|---|

| Heat Transfer Efficiency | 90 | % |

| Pressure Drop | 5 | kPa |

| Material Cost | 1500 | USD |

| Lifetime | 20 | Years |

| Energy Recovery Rate | 80 | % |

| Size | 1.5 | m² |

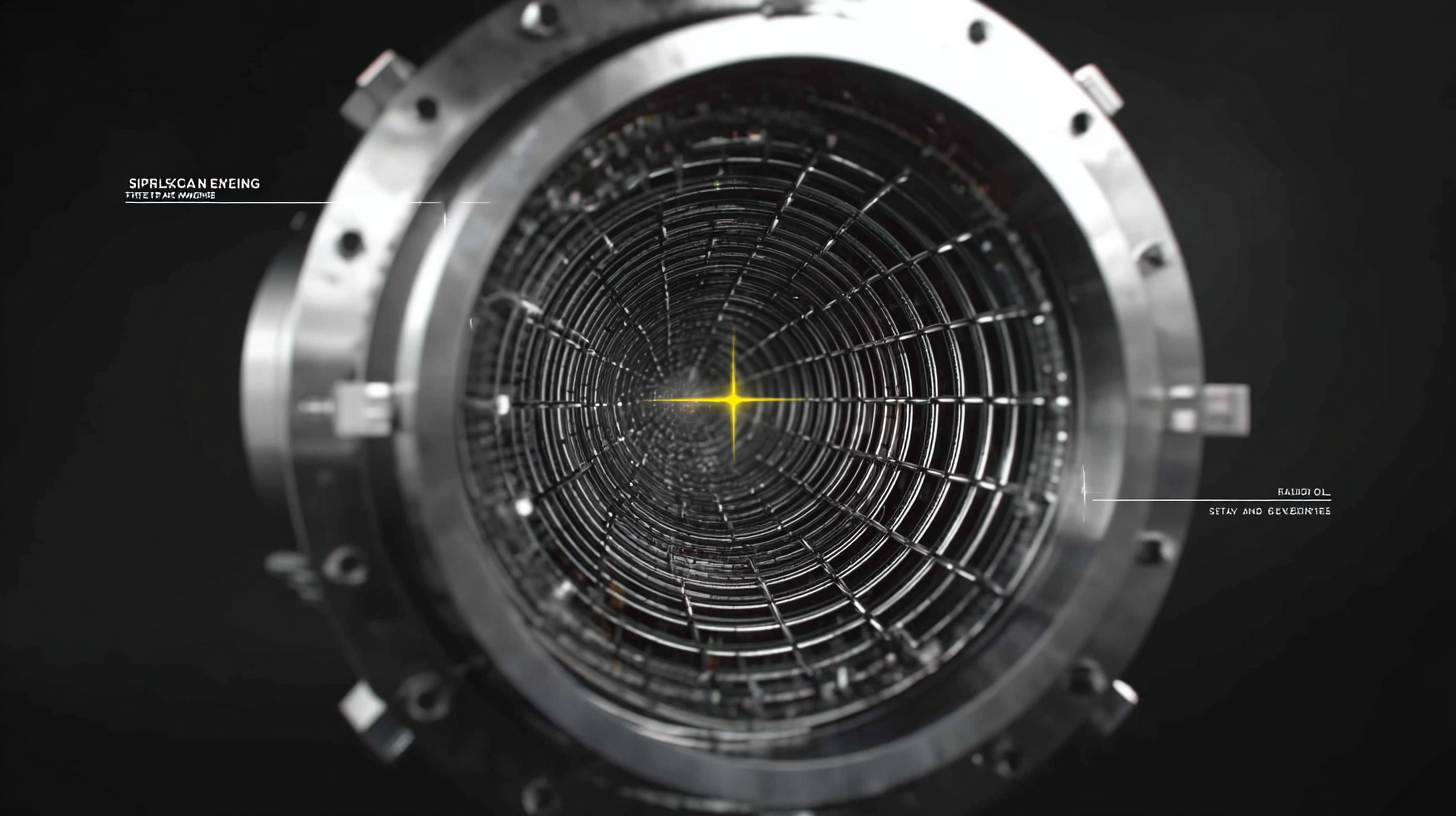

Understanding the Science: How Spiral Heat Exchangers Optimize Thermal Performance

Spiral heat exchangers have emerged as a crucial technology for optimizing thermal performance across various industrial applications. Comprising two spiral channels—one for the hot fluid and another for the cold fluid—these heat exchangers enhance the heat transfer surface area and improve fluid flow patterns, significantly increasing energy efficiency. According to a report by Research and Markets, the global heat exchanger market is projected to grow at a CAGR of 6.8% from 2020 to 2027, highlighting the rising demand for efficient thermal management solutions.

The efficiency of spiral heat exchangers can be attributed to their unique design, which allows for a greater turbulent flow and promotes effective heat transfer. A study published in the International Journal of Heat and Mass Transfer indicates that spiral heat exchangers can achieve up to 30% more thermal efficiency compared to traditional shell-and-tube designs. This efficiency is particularly beneficial in industries such as petrochemicals, pharmaceuticals, and food processing, where optimized thermal performance not only leads to reduced energy consumption but also lowers operational costs. With advancements in materials and design, the future of spiral heat exchangers looks promising, paving the way for enhanced energy efficiency in a sustainable manner.

Key Industry Statistics: The Impact of Efficient Heat Exchange on Energy Savings

The impact of efficient heat exchange on energy savings is becoming increasingly critical in the current landscape of energy consumption, particularly in the construction sector. As the demand for energy efficiency escalates, data reveals that the construction industry is experiencing rapid growth in building energy-saving initiatives. In this context, spiral heat exchangers have emerged as a game changer, offering enhanced thermal performance while maintaining compact designs that cater to high-density applications.

Recent reports highlight a projected expansion of the building energy-saving market, driven by the need for innovative solutions that comply with strict energy efficiency regulations. Heat exchangers, particularly the spiral variant, play a crucial role in optimizing energy utilization across various systems, leading to substantial savings. As industries pivot towards sustainability, the adoption of efficient heat exchange technologies is not just a trend but a strategic imperative that aligns with global efforts towards reducing carbon footprints and promoting energy stewardship.

Innovations in Design: Advancements in Spiral Heat Exchanger Technology

The advancements in spiral heat exchanger technology are transforming the landscape of energy efficiency across various industries. By integrating innovative design elements, recent developments have enhanced the thermal performance and operational reliability of these devices. The spiral configuration allows for a more compact design, which not only saves space but also leads to more effective heat transfer. This design minimizes pressure drops and energy losses, thereby optimizing overall system performance and reducing operational costs.

Furthermore, the use of advanced materials in construction has improved the durability and resistance of spiral heat exchangers to corrosive fluids, extending their lifespan and reliability in demanding environments. Innovations such as enhanced surface patterns and modular designs are also paving the way for customization to meet specific requirements of different applications. These advancements not only address the growing need for sustainable energy solutions but also empower industries to achieve their efficiency goals while minimizing their environmental footprint. As these technologies evolve, the future of energy efficiency looks promising.

China's Role in Global Manufacturing: Consistent Quality in Spiral Heat Exchangers

As the global demand for efficient energy solutions rises, China is establishing itself as a critical player in the manufacturing of spiral heat exchangers. Recent major events, such as the CTEF Shanghai Chemical Exhibition, have highlighted the leading brands in the heat exchanger industry, showcasing a comprehensive range of products and innovations. Notably, a significant proportion of the world's spiral heat exchangers are produced in China, with industry reports indicating that the country accounted for over 30% of global production in 2022. This statistic underscores China's vital role in maintaining consistent quality and advancing technological development in the sector.

Furthermore, the entry of European companies into the Chinese market reflects a growing recognition of the country's capabilities. With their simple structures and ease of operation, spiral heat exchangers made in China are not only cost-effective but also help users minimize maintenance costs significantly. The presence of both domestic and international players fosters a competitive environment that drives continuous improvement and innovation, ensuring that the products meet high standards of efficiency and reliability. As the industry rapidly evolves, China remains at the forefront, ready to set new benchmarks in energy efficiency for spiral heat exchangers globally.