Unveiling Top 8 Specifications of the Best Spiral Tube Reactor for Global Buyers

In recent years, the demand for efficient and innovative chemical processing technologies has surged, with the Spiral Tube Reactor emerging as a frontrunner in this evolution. According to a report by Research and Markets, the global market for chemical reactors is projected to reach $10.9 billion by 2025, driven by the increasing need for energy-efficient solutions and sustainable practices. The unique design of Spiral Tube Reactors, which enhances mass and heat transfer while minimizing reaction times, plays a crucial role in this growth. Furthermore, the ability to maintain precise temperature control and increased surface area allows for greater reaction efficiency and product yield. As global buyers seek cutting-edge technology to improve their manufacturing processes, understanding the top specifications of the best Spiral Tube Reactors is essential for informed investment decisions.

Top Factors Influencing the Selection of Spiral Tube Reactors for Global Buyers

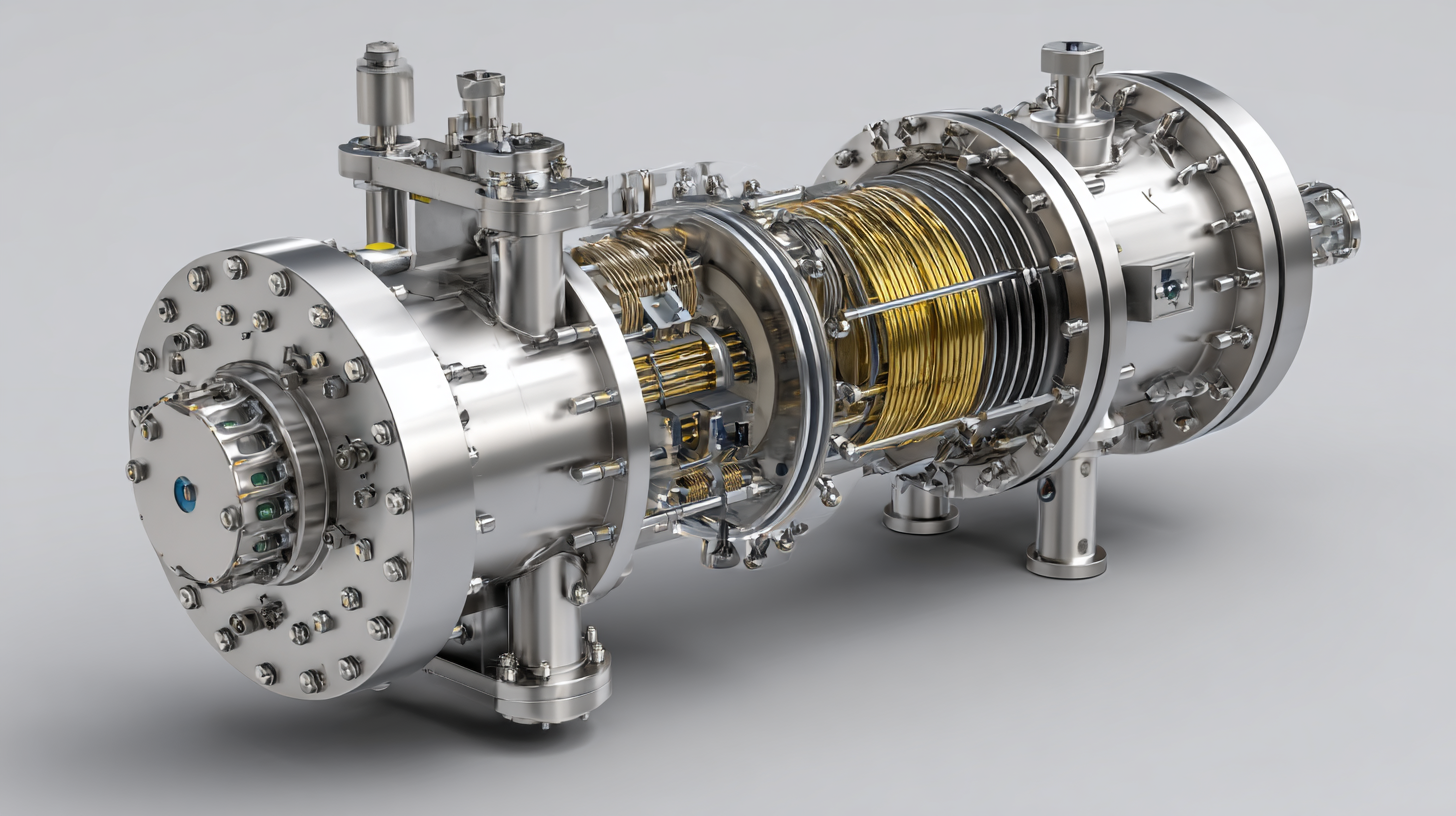

When selecting a spiral tube reactor, several critical factors come into play that can significantly influence buyers' decisions. The design and material of the reactor are paramount, as these determine chemical compatibility, temperature resistance, and overall durability. For instance, reactors made from high-grade stainless steel or specialized alloys can withstand harsh reactions and prolong operational life.

Additionally, the reactor's configuration, including the length and diameter of the spiral tubes, directly impacts mixing efficiency and reaction times, making it essential for buyers to align these specifications with their specific process requirements.

Additionally, the reactor's configuration, including the length and diameter of the spiral tubes, directly impacts mixing efficiency and reaction times, making it essential for buyers to align these specifications with their specific process requirements.

Another important consideration is the reactor’s scalability. Buyers must assess whether the system can accommodate varying production levels without compromising performance. Automation features should also be examined, as advanced control systems can enhance precision and ease of operation. Furthermore, energy efficiency is a growing concern in today's market, and a reactor designed to minimize energy consumption can provide significant cost savings in the long run. Evaluating these factors will help global buyers make informed decisions, ensuring they select a spiral tube reactor that meets their operational needs effectively.

Key Specifications for Enhanced Efficiency in Spiral Tube Reactors

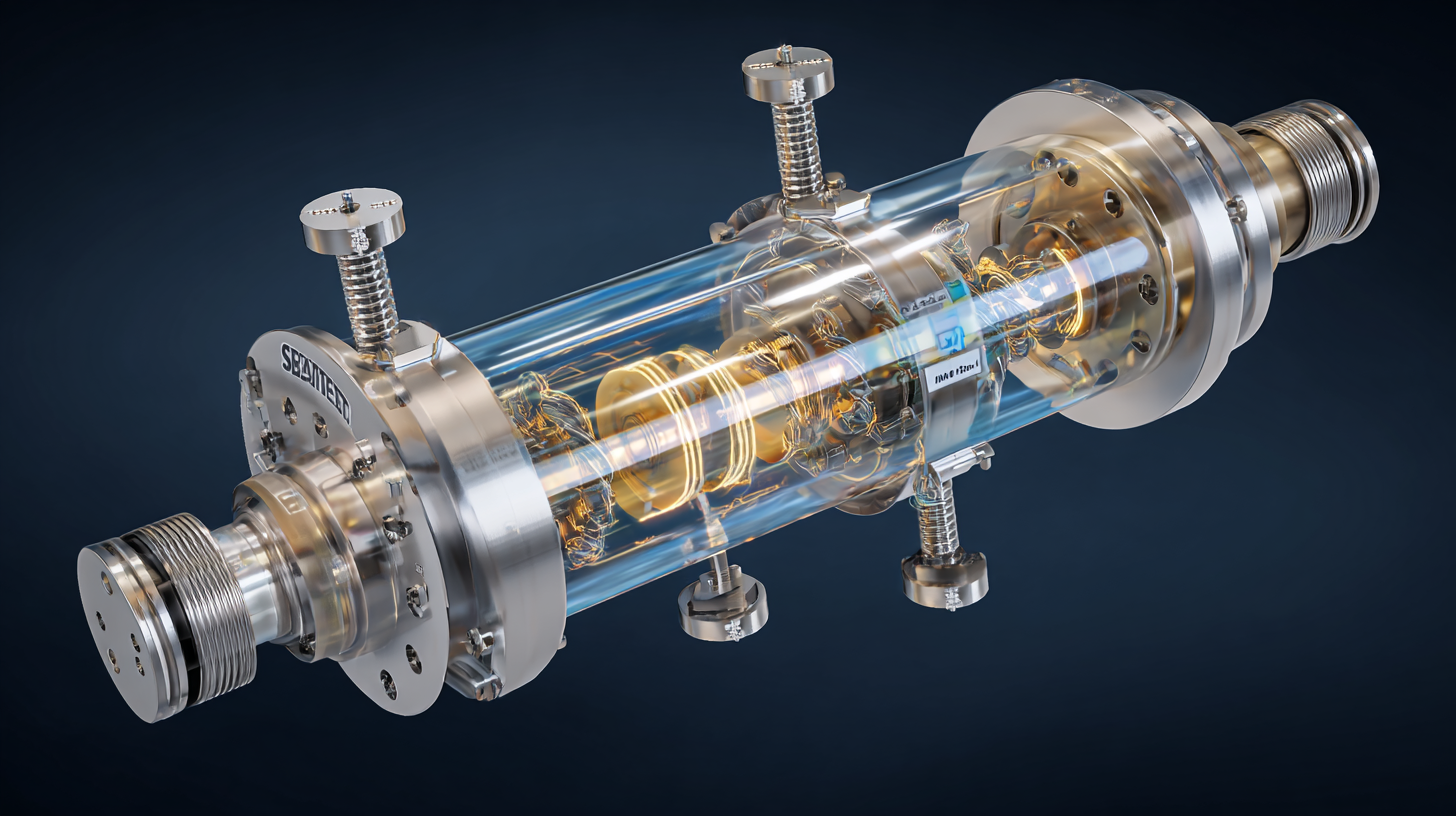

When considering the purchase of a spiral tube reactor, understanding the key specifications is crucial for ensuring enhanced efficiency and optimal performance. A recent industry report revealed that reactors with a precise tube geometry can significantly enhance mass transfer rates, which is vital for reactions that require high precision and output quality. This specification not only minimizes pressure drop but also maximizes surface area for interaction, leading to improved reaction kinetics. Typical diameters for these reactors range from 5 to 50 mm, depending on the application, which can influence both scalability and energy efficiency.

Another critical specification is the material of construction. According to the 2023 Global Chemical Engineering Analysis, reactors made from high-grade stainless steel or specialized alloys are essential for handling corrosive substances while providing longevity and durability. Furthermore, the choice of temperature and pressure limits can directly impact the reactor's efficiency; modern designs often accommodate temperatures exceeding 200°C and pressures up to 30 bar, thus allowing for a wider range of chemical reactions to occur under controlled conditions. The integration of advanced monitoring systems such as temperature sensors and pressure transducers further enhances operational efficiency and safety, making these reactors a preferred choice for chemical manufacturers worldwide.

Unveiling Top 8 Specifications of the Best Spiral Tube Reactor for Global Buyers

| Specification | Description | Value |

|---|---|---|

| Reactor Volume | Total internal volume of the reactor | 1000 L |

| Heat Exchange Area | Surface area for heat transfer | 200 m² |

| Flow Rate | Maximum permissible flow rate through the reactor | 1500 L/h |

| Pressure Rating | Maximum operating pressure | 10 bar |

| Material of Construction | Material used for reactor fabrication | Stainless Steel 316L |

| Temperature Range | Operating temperature range of the reactor | -20 to 200 °C |

| Agitation Type | Type of mixing used within the reactor | Mechanical Agitation |

| Control System | Type of control system integrated | PLC Based |

Understanding the Importance of Material Selection in Reactor Performance

Material selection is pivotal in the performance of spiral tube reactors, influencing their efficiency, longevity, and ability to withstand harsh operational conditions. Recent advancements have showcased the critical role of advanced materials in enhancing reactor design, particularly in addressing the extreme environments commonly encountered in various industrial applications. For instance, the utilization of ceramic materials like beryllium oxide offers exceptional high-temperature radiation stability, making them suitable for reactors operating under demanding conditions, such as those found in next-generation nuclear power plants.

Moreover, the integration of innovative configurations and advanced materials in electrochemical systems is progressively improving CO2 conversion processes. By selecting the right materials for reactors, manufacturers can optimize efficiency and effectiveness in chemical production, including photocatalytic hydrogen evolution processes. The focus on material properties and their interactions within the reactor environment is essential not only for maximizing output but also for ensuring stability and scalability in industrial applications, paving the way for sustainable technological advancements in reactor performance.

Comparison of Material Impact on Reactor Performance

Cost-Benefit Analysis: Investing in the Best Spiral Tube Reactor

Investing in a high-quality spiral tube reactor can yield significant long-term benefits for global buyers. These reactors are designed to optimize heat transfer and enhance chemical reactions, making them an indispensable component in various industrial applications. Conducting a cost-benefit analysis reveals that, while the initial investment might be higher than traditional reactors, the efficiency gains and reduced operational costs often justify the expense. Companies can achieve lower energy consumption and improved output, which translates to considerable savings over time.

When evaluating the best spiral tube reactor for your needs, it's essential to consider a few key specs. Focus on materials that offer durability and thermal efficiency, as these will directly impact performance and maintenance costs. Additionally, assess the technology used in the design that maximizes the heat exchange process, such as enhanced surface area and flow dynamics.

**Tips:** Prioritize suppliers that provide comprehensive warranties and support services, as this can secure your investment and ensure longevity. Also, explore customizable options to meet specific production requirements, as this flexibility can further enhance operational efficiency and expand your product capabilities.

Innovative Features That Set Premium Spiral Tube Reactors Apart

In the rapidly evolving world of chemical engineering, spiral tube reactors have emerged as a cornerstone technology for efficient mixing and reaction processes. The best models offer innovative features that not only enhance performance but also optimize energy and resource utilization. One standout aspect is the advanced heat transfer capability, which significantly reduces temperature gradients inside the reactor. This results in more consistent product quality and can minimize the risk of thermal degradation, a common concern in traditional reactors.

Another critical feature is the modular design of premium spiral tube reactors, allowing for easy scalability and customization. Buyers can adapt the reactors to their specific needs, whether for pilot projects or large-scale production. Furthermore, advanced monitoring systems equipped with real-time data analytics ensure precise control over reactions, leading to improved yield and reduced operational costs. These innovations exemplify how modern spiral tube reactors are not only meeting the demands of today’s marketplaces but are also setting new standards for safety, efficiency, and sustainability in industrial processes.